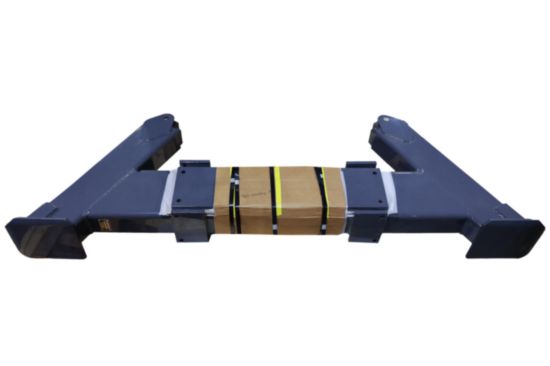

Outrigger Assemblies for Crane Trucks, Boom Trucks & Heavy Equipment

Outrigger assemblies are complete support-system packages for crane trucks, boom trucks, aerial lifts and other heavy equipment. At Custom Truck One Source, our “Outrigger Assemblies” category offers fully engineered assemblies — including beams, center posts, jacks/legs, pads, and mounting hardware — designed to provide stability, safety and proper load support for lifting and stabilization operations.

What Is an Outrigger Assembly and Why It Matters

An outrigger system transforms a mobile crane or truck-mounted lift into a stable, ground-anchored lifting platform by extending support structures outward and downward to create a wide, stable base. Without outriggers, cranes rely solely on their tires or tracks — significantly reducing lifting capacity and increasing risk of tipping.

An “Outrigger Assembly” bundles all necessary structural components — beams, center posts/tubes, hydraulic jacks/legs (or mechanical supports), pads/feet and mounting hardware — into a ready-to-install kit. This packaged approach simplifies installation or retrofit, ensures component compatibility, and helps maintain structural integrity and safety compliance.

Key Features & Specifications to Consider

When selecting an outrigger assembly for a crane truck or heavy equipment, make sure it includes and meets:

-

Full system components: beams (outrigger spreaders), center posts/tubes, jacks or legs (hydraulic or mechanical), outrigger pads/feet, mounting brackets and hardware.

-

Structural strength & duty-rating: Components fabricated from structurally rated steel or equivalent materials; weld quality, wall thickness, and load-rating capacity should match or exceed equipment lifting requirements.

-

Proper geometry and fitment: Assembly must match truck/chassis dimensions, mounting points, jack spacing, and overall footprint needs for the vehicle or crane model.

-

Hydraulic/ mechanical reliability (if applicable): Jacks or legs should be rated for heavy loads, have appropriate stroke length/extension, seal and seal-housing to resist weather, and be compatible with the vehicle’s hydraulic or control system.

-

Ground support capability: Outrigger pads or feet should distribute load appropriately (especially on softer or uneven ground), and assembly should include or recommend proper support mats/pads when required.

-

Complete mounting hardware & alignment assistance: Proper bolts, weld brackets or flanges so the assembly integrates securely with the chassis/frame, ensuring safety and longevity.

Safety, Maintenance & Use Guidelines

To ensure safe and effective operation:

-

Always deploy outriggers fully before lifting — improper or partial deployment is a leading cause of crane tipping accidents.

-

Use appropriate outrigger pads or mats under feet — this distributes ground pressure, especially on soft or uneven terrain, minimizing risk of sinking or instability.

-

Inspect the entire assembly before each lift — check welds, beams, posts, legs/jacks, pads/feet, bolts and mounting hardware for cracks, deformation, corrosion or wear.

-

Confirm hydraulic or mechanical components (if included) are functioning properly — jacks should extend/contract smoothly, seals intact, legs lock securely, and load per jack should not exceed rating.

-

Keep records of inspections, maintenance, load-history and any repairs — helps maintain safety history and supports preventive maintenance planning.

Why Choose Custom Truck One Source for Outrigger Assemblies

-

We supply complete, heavy-duty outrigger assemblies engineered for crane trucks, boom trucks, aerial equipment and other heavy work rigs — ensuring you get all necessary components in one kit.

-

Our parts-specialist team understands crane and heavy-equipment load requirements, helping you select the right assembly for your vehicle or job-site needs.

-

With nationwide distribution and reliable inventory, we support quick delivery and retrofit turnaround — minimizing downtime when you need to replace or upgrade your outrigger system.

-

Bundling beams, center posts, jacks, pads and hardware together helps ensure compatibility, structural integrity and load-rating compliance — reducing risk over piecemeal sourcing.

Browse & Order Today

Explore our selection of outrigger assemblies — filter by vehicle or crane type, boom configuration, outrigger spread width, jack type (hydraulic or mechanical), and part number. Place your order online or call our parts team at 877-831-0572 for help with fitment, load-rating verification or installation guidance.

LOCATIONS

LOCATIONS