Rail maintenance is an ongoing job for railroad section crews. Constant commuter & freight traffic means constant wear and tear on rail networks. Tasked with maintaining a certain number of track miles, each crew may be required to swap out sticks of rail, remove and replace railroad spikes, install rail frogs, or perform one of many other duties. Rain or shine, they must be ready at a moment’s notice. A section truck isn’t merely a mode of transportation, it’s a critical tool in the crew’s arsenal. When equipped with one of our hi-rail section trucks, these crews are outfitted with the tools they need to get the job done. One such truck is the 609V2.

609V2 Section Truck Specs

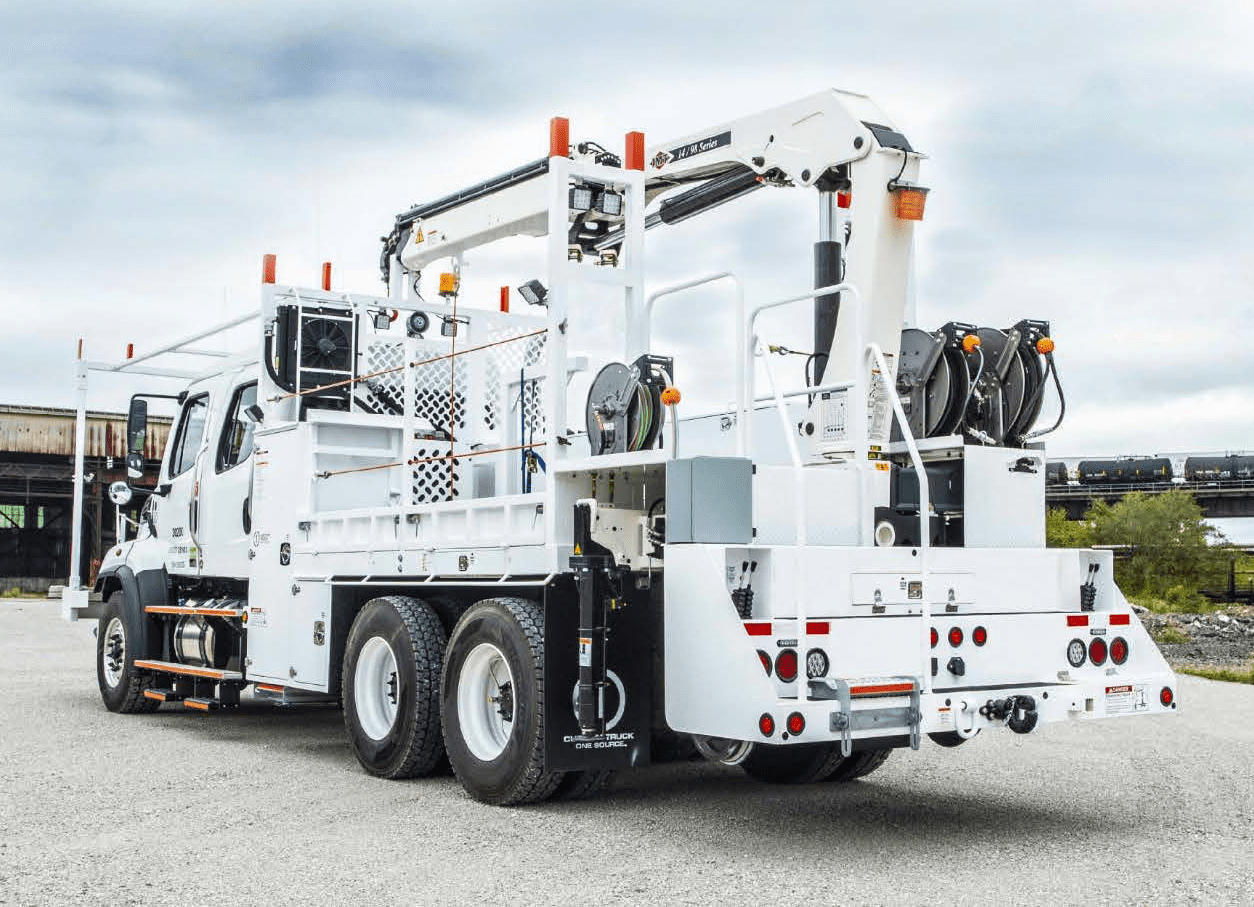

The 609V2 is a heavy duty section truck, typically a Freightliner chassis outfitted with an Ultrashift automated manual transmission and PTO provision, that features an articulating crane, oxy/acetylene hose system, hydraulic tool circuits, outriggers, and a set of heavy-duty rail gear. The cab’s interior features a multi-switch dash panel, a center console lockbox, crane remote battery charging bay, a reversing camera with two views (reward & hi-rail), and an inverter.

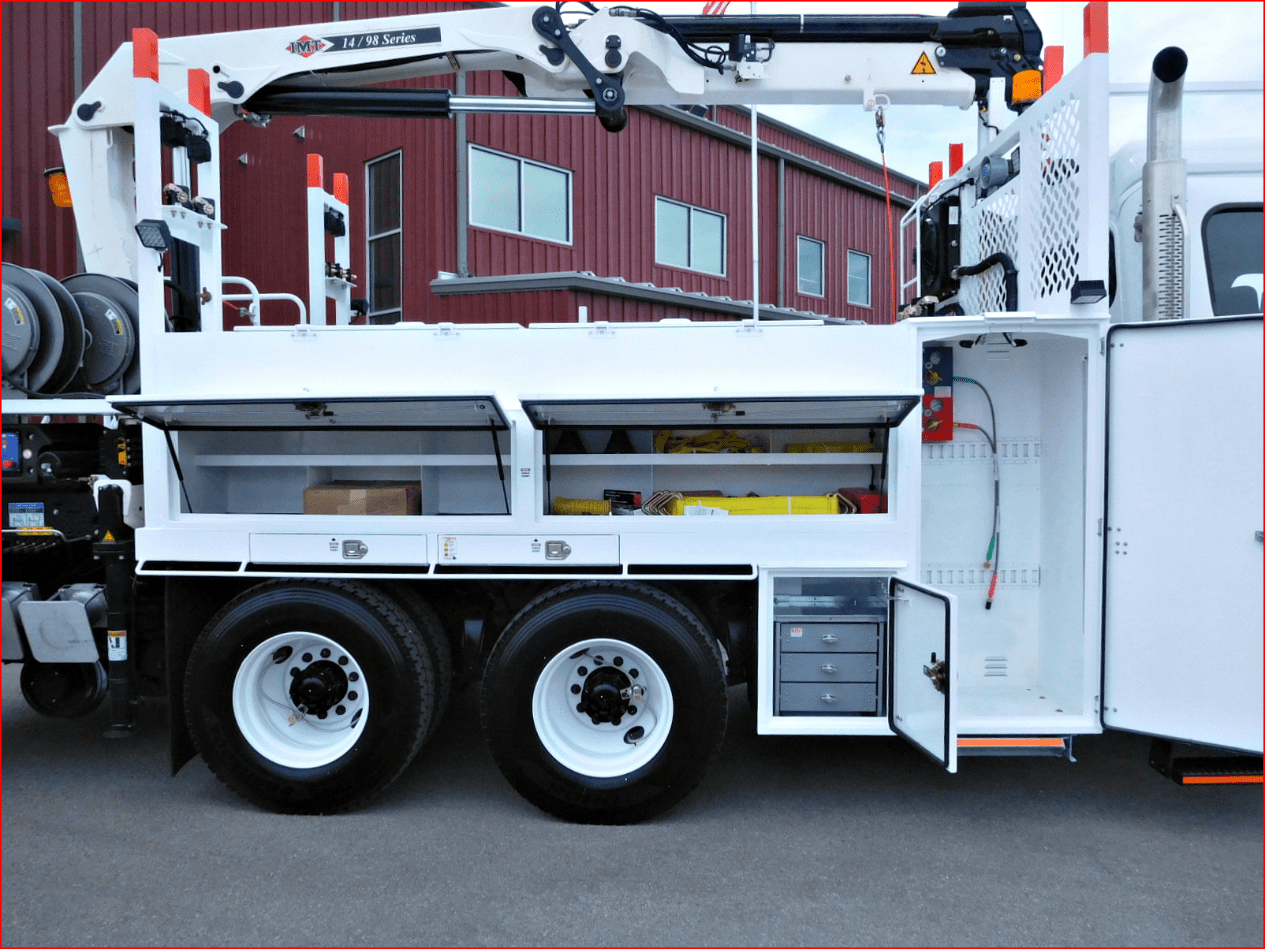

Given a crew’s large list of duties, storage is always a concern. The truck’s body has multiple storage compartments throughout. The front of the truck hosts a derailer mount. The rear of the body features one long bar compartment and a miscellaneous storage bin. One vertical compartment with an adjustable shelf and tool holders, an underbody box, and a long bar compartment comprise the streestside portion. The curbside features one vertical oxy/acetylene compartment, an underbody box with a three-drawer tool box, two horizontal compartments, and additional access to the long bar compartment. The bed also boasts an ample amount of storage space with its two storage bins, sign holder, tong holder, and rail expander mount. Material such as rail sticks and frogs are stowed in the H-Frame Material Rack and tied down via heavy duty straps and mounted ratchets.

The IMT Articulating Crane

The crew can handle such material due to IMT’s articulating crane. Synced with the RCL system, the crane may be operated with a remote control, which includes control over the following functions:

- Crane Rotation

- Primary and Secondary Boom Articulation

- Boom Extension

- Operation Speed Toggle (4 Creep Levels)

- Crane Spotlight Toggle (Momentary/Permanent)

- Tool Circuit Toggle

- Emergency Shutdown

Prior to delivery, CTOS inspectors load test the crane at each angle, at multiple extensions, to provide the operator with max lift guidelines. As an extra measure, the RCL employs an electronic overload protection system, mitigating risk of overloads during crane operation.

Extra Section Truck Features

Rear Features

The rear of the truck also hosts a multitude of features. An oxy/acetylene hose reel, which is mounted atop the rear-streetside corner of the body, ties into the curbside storage compartment, facilitating torch work at the rear of the vehicle. Two pairs of outrigger control levers are situated at both sides of the body’s rear, providing the operator a superior vantage when deploying/adjusting outriggers. A rear-access walk-up with handrailing and a fold-down step provides members easy and safe passage to and from the bed of the truck.

A long bar storage compartment is at the center-rear of the body, between the two outrigger control levers, and complements the curbside/streetside compartments. A detachable hydraulic tool holder rests at the rear, providing a convenient place to holster Spike Pullers, Spike Hammers, etc. Two hydraulic tool circuit spring rewind reels, which both feature 50 feet of hose, are mounted on the rear-curbside of the truck. These tool circuits feature an adjustable 5/10 GPM (Gallon Per Minute) flow rate. You can adjust the circuits’ flow rate manually at an enclosed switch panel, which is on the rear-streetside of the truck, or remotely with the RCL remote (more details below).

Switch Panel

The switch panel presents a combination of selector switches, indicator lights, and a pressure gauge. The detailed component list includes:

- Tool Circuit #1 Selector Switch (5 GPM/ Off / 10 GPM)

- Tool Circuit #2 Selector Switch (5 GPM / Off / 10 GPM)

- Rail Gear Selector Switch (On / Off)

- Rear Lights Selector Switch (On / Off)

- Crane Selector Switch (On / Off)

- Filter Ok Indicator Light

- Replace Filter Indicator Light

- Tools Disabled Indicator Light

In the pursuit of providing convenience to the operator, the switch panel, tool circuit, and RCL system have been integrated, providing remote toggle control over the tool circuit and boom-tip light with the flick of a switch from the RCL remote.

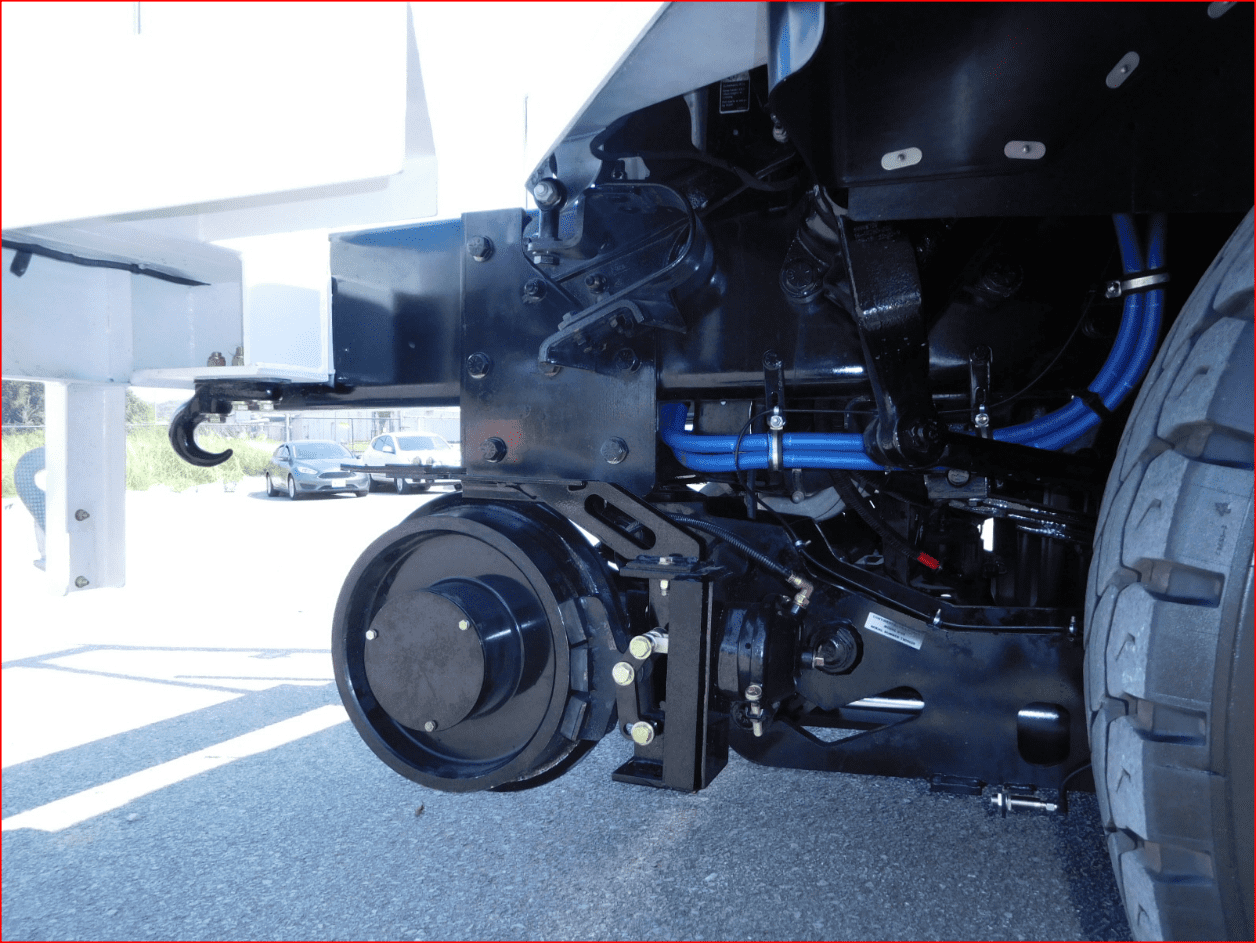

Rail Gear

With a constant focus on streamlining design and functionality, we’ve decided to outfit the V2 with Continental’s G-60 Rail Gear. The G-60 features an automatic mechanical lock. This mechanical lock employs a slot design instead of pins/lock-ups. Whether in highway or rail position, the geometry of the slot utilizes the gear’s gravity to lock it in place. This pinless design achieves two things:

- Simplifies the process of locking and unlocking gear, saving the operator precious time during stowing or deployment.

- Significantly reduces the lifetime maintenance cost associated with pin repair/replacement.

There is also an in-cab retraction option that reduces instances of manual retraction at crossings. The G-60 also features a positive downforce system. Rubber springs exert a significant downward force on the axle when the truck’s outer dually climbs onto an obstacle, which assists in maintaining constant gear-to-rail contact at troublesome areas like high crossings and guarded frogs. This feature reduces risk of derailment, by helping to maintain a constant hi-rail to rail contact at high crossings, guarded frogs, etc.

The rail network that traverses this country often evades the focus of those who rely on it. Typically, it only becomes a fixture in our minds when a travelling train stops us at a crossing. We often don’t think of the relationship between the rail network and our everyday lives. We don’t think about how bulk commodities make it from point A and B, from one coast to the other. That’s because we don’t have to worry about it. The section crews we spoke of above alleviate that worry; and they do it safely with trucks like the 609V2.

Could your Crew use a new section truck?

Call or Email us!

Custom Truck One Source is the first true single-source provider of specialized truck and heavy equipment solutions for railroad maintenance.

Hi-Rail equipment offered:

- Pick Ups

- Track Inspector

- Section Trucks

- Digger Derrick

- Hydraulic Excavator

- Material Handler

- Mechanic’s Truck (hi-rail optional)

- Rotary Dump Truck

- Signal Maintainer

- Supervisor SUV

With sales, rentals, aftermarket parts and service, equipment customization, remanufacturing, financing solutions, and asset disposal, our team of experts, vast equipment breadth and integrated network of locations across North America offer superior service and unmatched efficiency for our customers.