Residential roofing has always been back-breaking work: climbing up and down ladders, hauling 80 lb. bundles of shingles and tiles, risking falling off scaffolds and roofs, and exposure to extreme weather. And yet, houses must be built, and the work must go on.

This was the scenario until OSHA stepped in and banned the manual transport of heavy roofing material in the United States. Pulleys, hoists, and lifts were subsequently used to minimize risk of injury. However, unless they met OSHA guidelines, contractors that used them (or even worse, DIY-ed them) were exposing themselves to the possibility of heavy fines and legal reprimands.

They also didn’t accelerate job completion and required an excessive number of workmen to be onsite, so they weren’t particularly efficient. What the industry needed was a mechanical device that safely and swiftly got the job done.

This solution for the roofing industry is roofing conveyors, or truck-mounted conveyors.

WE INTERVIEWED DAVE TAFF, VP OF BUILDING MATERIALS AT CUSTOM TRUCK, ABOUT LOAD KING’S ROOFING CONVEYORS – ONE OF THE LEADERS IN THIS SECTOR.

Excerpts from the interview:

Load King’s roofing conveyors are available in what lengths?

Standard Load King Conveyor lengths are 37 feet, 40 feet, & 43 feet. Customized lengths are also available upon customer request.

Can Load King’s roofing conveyors be built to carry a truck-mounted forklift in conjunction with a conveyor?

Yes, a 37’ Conveyor Package can be built to accept a truck-mounted forklift kit, allowing the customer to utilize their Conveyor Package for the dual purpose of offloading materials.

What are the advantages of Load King’s 360-degree continuous rotation design?

A 360-degree continuous rotation allows for quicker setup and stowing of the conveyor boom. It also allows for repositioning of the conveyor boom for offloading without the need to stow the conveyor and reposition the truck.

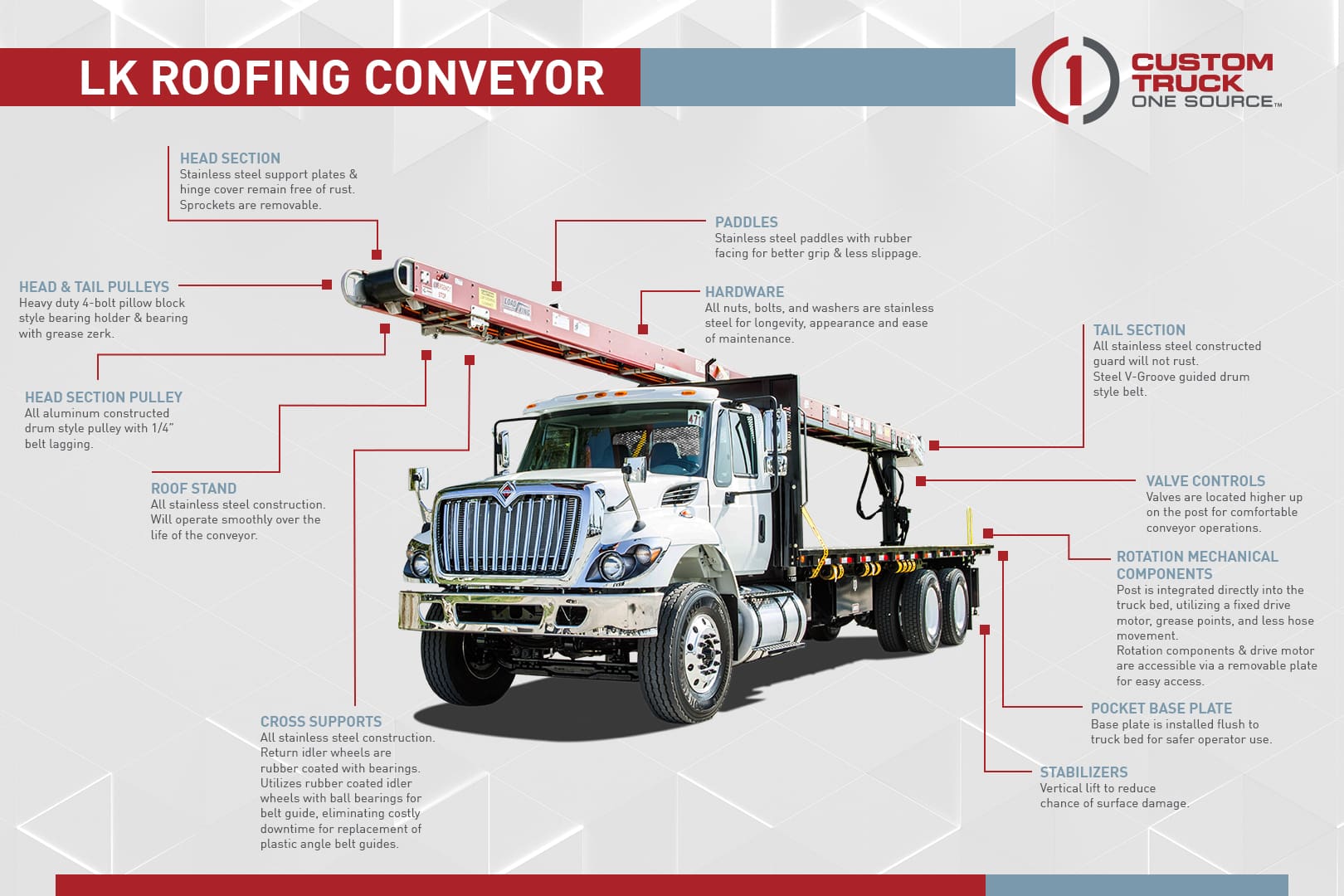

What are the advantages of stainless steel hardware, supports, guards, paddles, and roof stands?

Stainless steel components remain free of rust and improve longevity, appearance, and ease of maintenance.

Why is the control valve located higher up on the post than most of your competitors?

Our equipment was designed with ergonomics in mind. With the control valve mounted higher on the post, excessive bending and kneeling is reduced, allowing for safer and more comfortable operation.

What is the purpose of the removable `access plates’ located around the conveyor rotation system?

This is for ease of maintenance. The `access plates’ allow for easy access from the top of the conveyor deck to the rotation gear, rotation motor, grease points, etc. So, there’s no need for crawling around on the ground under the truck body if you’re going with a Load King roofing conveyor.

Why would I want outriggers with a `Vertical Lift’ design as opposed to the `Arch-style’ design used by most of your competitors?

The Arch-style design’s radius draws in as the truck is stabilized, increasing chances of surface damage due to slippage of the outrigger pads. The `Vertical Lift’ design, in contrast, deploys and retracts vertically, reducing the risk of surface damage with no outrigger pad slippage.

What is the benefit of the `heavy duty 4- bolt pillow block’ style bearing holder, with grease zerk on the head and tail section pulleys?

The `heavy duty 4-bolt pillow block’ design is more robust for prolonged life of the pulley bearings and increased ease of maintenance or replacement in the event of a bearing failure.

What are the benefits of the all-aluminum drum style belt pulleys with ¼’ belt lagging?

The all-aluminum design is more robust than other designs utilizing `rubber wheels’ on a steel drive shaft. This design increases longevity and reduces maintenance costs. The ¼’ belt lagging provides more positive contact with the conveyor belt, which reduces belt `slippage’

What is the purpose of the roof stand?

The roof stand distributes the weight of the load across the span of the roof to reduce unnecessary wear on the conveyor boom and its components. It also provides stability to the conveyor boom for easier offloading of materials.

Machines need regular care to perform optimally and to extend their working life. At Custom Truck, we are always urging our customers to read the manual that comes with the unit and follow its guidelines. Your roofing conveyor is a workhorse, and the last thing you want is downtime because of extensive – and expensive – repair or replacement. Below, we have suggested a few things to keep in mind:

There are some options (mechanisms like platforms, lifts, and pulleys) to hoist asphalt shingles, tiles, and metal panels up to the roof. But they are not well-suited for roofing companies, roofing contractors, and roofing suppliers, for whom speed and safety are primary concerns. Roofing conveyor trucks offer an alternative that significantly speeds up the process.

Using a roofing conveyor may reduce labor costs, as fewer workmen are required to be onsite to operate deliveries.

The material of choice used to make roofing conveyors is fiberglass. With enhanced mechanical strength, it can out-perform most other materials. Weather-proof, fire-resistant, and long-lasting, fiberglass also does not rust, which means reduced repair costs.

Roofing conveyors protect your investments from theft, as the material is delivered so efficiently via a conveyor belt.

The facts may shock you. As part of the roofing industry, you already know the job isn’t easy. But taking a closer look at the industry stats might propel you to take action and invest in heavy equipment (or rent from a safe and efficient delivery service that uses roofing conveyers, if you’re a roofer). This will not only save you money, but possibly save lives.