Unplanned downtime is probably a jobsite manager’s worst nightmare. When work stops, schedules go awry and the cost of projects goes up – all because a crucial piece of equipment has failed. The problem gets worse still if the equipment has to be transported to a central shop for repair or refurbishment.

This is the type of situation in which service or mechanics trucks come to the rescue.

Like ambulances at the scene of an accident, they take repairs on the road. Mechanics trucks & service trucks carry mechanics, along with any necessary parts and tools, to the jobsite to service broken machinery that cannot be easily transported.

They have various compartments and tool bins to carry required materials and often feature a crane that can lift and move heavy equipment parts.

From mining operations to highway support, rail, and civil utility, mechanics trucks are useful assets. The value these trucks bring to jobsites experiencing a breakdown, by saving time, money, and work momentum, is hard to deny. Which is why not only equipment dealers and large contracting companies buy them. A growing number of independent mechanics these days offer onsite services, too, expanding the scope of mobile repair with the help of a well-equipped service truck.

Here’s a handy FAQ we have compiled for you, with questions answered by Mark Partlow, the Product Manager for Service & Mechanics Trucks at Custom Truck One Source (CTOS).

What kinds of companies use service & mechanics trucks?

Typically, anybody who is working with what we call `yellow iron’ – heavy equipment that is in the field, hauling, moving dirt, building buildings, etc. uses a service truck. Such equipment cannot easily be brought to a central shop if it needs repairs or service, so it is simpler and more cost-effective to do it in the field.

What is the difference between a service truck and a mechanics body truck?

The two terms are sometimes used interchangeably. However, mechanics body trucks are more fully equipped than service trucks. A mechanics body typically means that it is a service body, a crane, and an air compressor. A service truck might not have a crane, but just a service body with tools and, possibly, an air compressor.

How do the sizes of cranes relate to sizes of trucks?

Smaller trucks, by definition, will support smaller cranes. Customers may buy as large a crane as feasible, but the size of the truck is the limiting factor. You can only put certain-sized cranes on certain-sized trucks. So, if they are lifting heavier loads, they need a bigger truck with a bigger crane on it. Another advantage of bigger trucks is that they have more room to carry tools and materials. These days, they typically feature both standard American tools and metric tools. They have two sets of wrenches and sockets, so they can work on everything.

What are cranes on mechanics used for?

Oftentimes, they are used to disassemble something. If mechanics are working on an excavator, for example, they might have to take the cab off. If they are working on a Bobcat, they might have to take the tracks off. It is usually pieces or parts of what make up the equipment that the crane lifts and moves.

How does CTOS help customers choose the right service truck or mechanics truck?

The first questions we ask are how big of a crane do you need, and what capacities are you going to be dealing with? That tells us what class of truck they’ll need, and we can match a crane corresponding to their job at hand. Then we ask what truck brand they’d like. Ford, Chevrolet, International, or Dodge? Because we have all four. We also ask about chassis preference. If they want a regular cab, an extended cab, or a crew cab. Four-wheel drive or two-wheel drive.

We try to get the chassis questions out of the way, so we can help them match equipment to the chassis they are looking at purchasing.

There are so many options these days, you have to ask those question to make sure you are best matching the customers’ needs.

What is Custom Truck One Source’s unique selling point when it comes to mechanics trucks?

Easy availability. We build units and have them on the ground at all times. Built and ready to go to work. Not a lot of mechanics truck companies do that.

IMT is probably one of the most high-quality mechanics bodies available in the market today. Everything – the body, crane, and compressor — comes from one supplier. They are very well-known as a leading manufacturer, and have been for the past 50 years.

The Voyager series, built by our manufacturing arm, Load King, is a more cost-effective alternative to the IMT Dominator. We’re using a quality crane and a quality compressor on a different body.

Mark Partlow, Product Manager for Service Trucks at Custom Truck One Source and the Load King Voyager I on the new Chevrolet 5500 were featured at ICUEE 2019. Check out the video below!

Steel is by far the most popular choice, because the material holds up the longest and requires the least amount of repair. The majority of the market is galvanneal steel bodies. A lot of work has been done to prevent rust on steel, with treatment, paint, compartment coating, etc. Much has been improved over the years to decrease rusting, but it is still the strongest and most long-lasting. The majority of mechanic bodies and service trucks offered at Custom Truck One Source are steel bodies.

Aluminum, in today’s market, is an alternative for people working in road conditions with salt, snow, and ice. There is a bit of weight savings, but not a lot for the extra money you’re going to pay, because aluminum is expensive. At CTOS and Load King, we use aluminum to supply the railroad market, because some railroad contractors specify the need for an aluminum crane body. Currently, we are also investigating the idea of an aluminum light-duty crane body. Not the `hybrid’ version that is available today, but all-aluminum. You couldn’t put as large of a crane on it, but it would look good for a long time and the weight advantage would be huge!

The Load King Voyager P, meanwhile, has aluminum boxes attached to a steel subframe with rumber flooring. This keeps the weight and the corrosion down, and the propane industry loves that. Introduced less than a year ago, it has become very popular and we’re seeing great success with it. In fact, we sold almost 100 units last year, and the feedback has been great.

As far as fiberglass is concerned, not many people opt for that material. Fiberglass is very expensive to repair. The door openings are smaller because of the reinforcements that are needed. Sure, they are lighter, but they don’t have the storage space that a steel or aluminum body would have. Fiberglass is primarily used in the utility industry because of weight and aesthetics. It looks good, it doesn’t rust, and the utility sector doesn’t require a lot of extra room inside like a mechanic does. So, it works better in a utility application than it does in other common service truck applications.

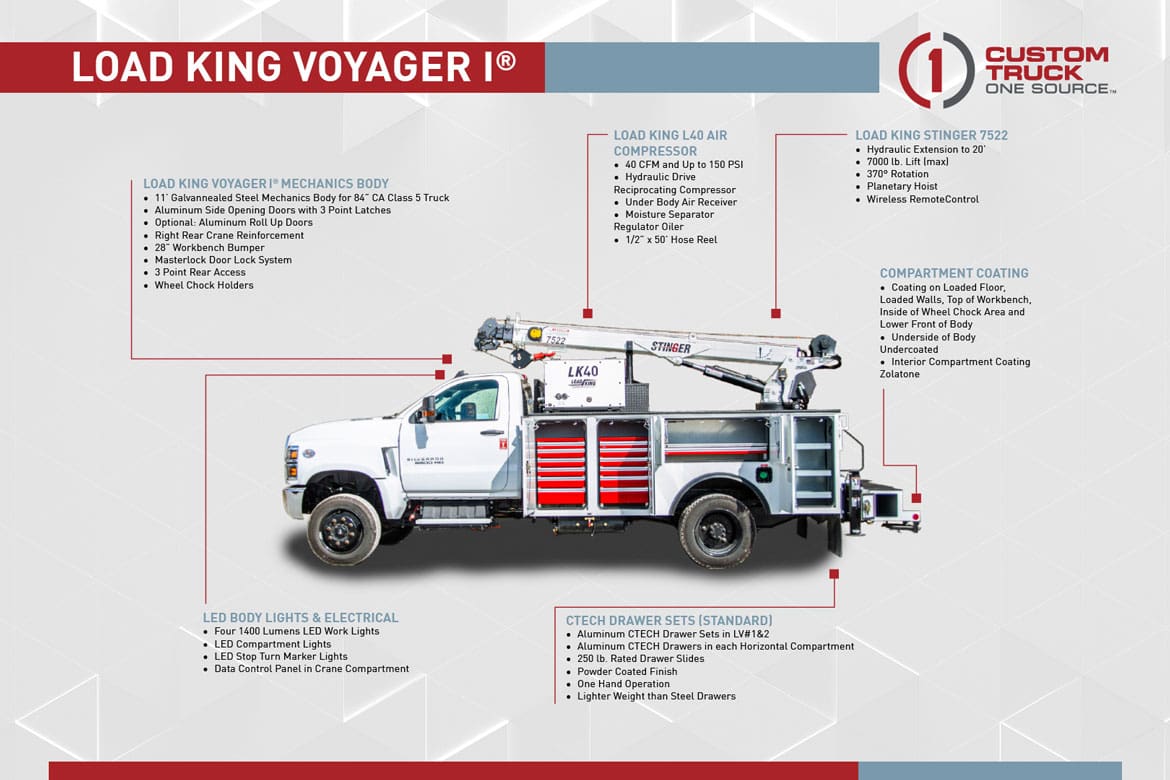

The Voyager® I mechanics body boasts an 11’ HD galvannealed steel crane body with a master lock system and right reinforced rear crane rated for 7,000 lbs. Lightweight, high-quality CTEC tool drawer sets come standard, as do unparalleled levels of coating coverage in the bed space. Load King’s inventive lighting and compartment designs offer superior compartment storage capacity and unmatched work area visibility.

The Voyager® II mechanics body features a 14’ HD galvannealed steel crane body with a master lock system and reinforced right rear crane offering 10,000 lbs. of rated capacity and 25’ of maximum horizontal reach. The Voyager® Series comes fully-loaded with high-performance standard features that offer significant payload savings and superior quality at a more competitive price.

The Voyager® P propane service truck boasts an all-aluminum bed, side rails and headache rack with E-Trac. The Auto Crane EHC-6 lifts up to 6,000 lbs., reaching 20.4 ft. fully extended. Standards include rumber flooring, concrete block storage holder under body, and LED compartment light kits in storage boxes.

Let Custom Trucks One Source, the first true, single-source provider of specialized trucks, help you make the right choice. We can assist you with financing options, too!