From home furnaces to warehouse forklifts – propane is the product that powers our lives, and during winter, the consumption of propane increases exponentially in both industrial and residential sectors, leading to price hikes and supply shortages.

January is a month when propane is an irreplaceable commodity. It keeps factories in operation and our homes warm and cozy, but it is also an extremely flammable material with explosive force in pressurized form.

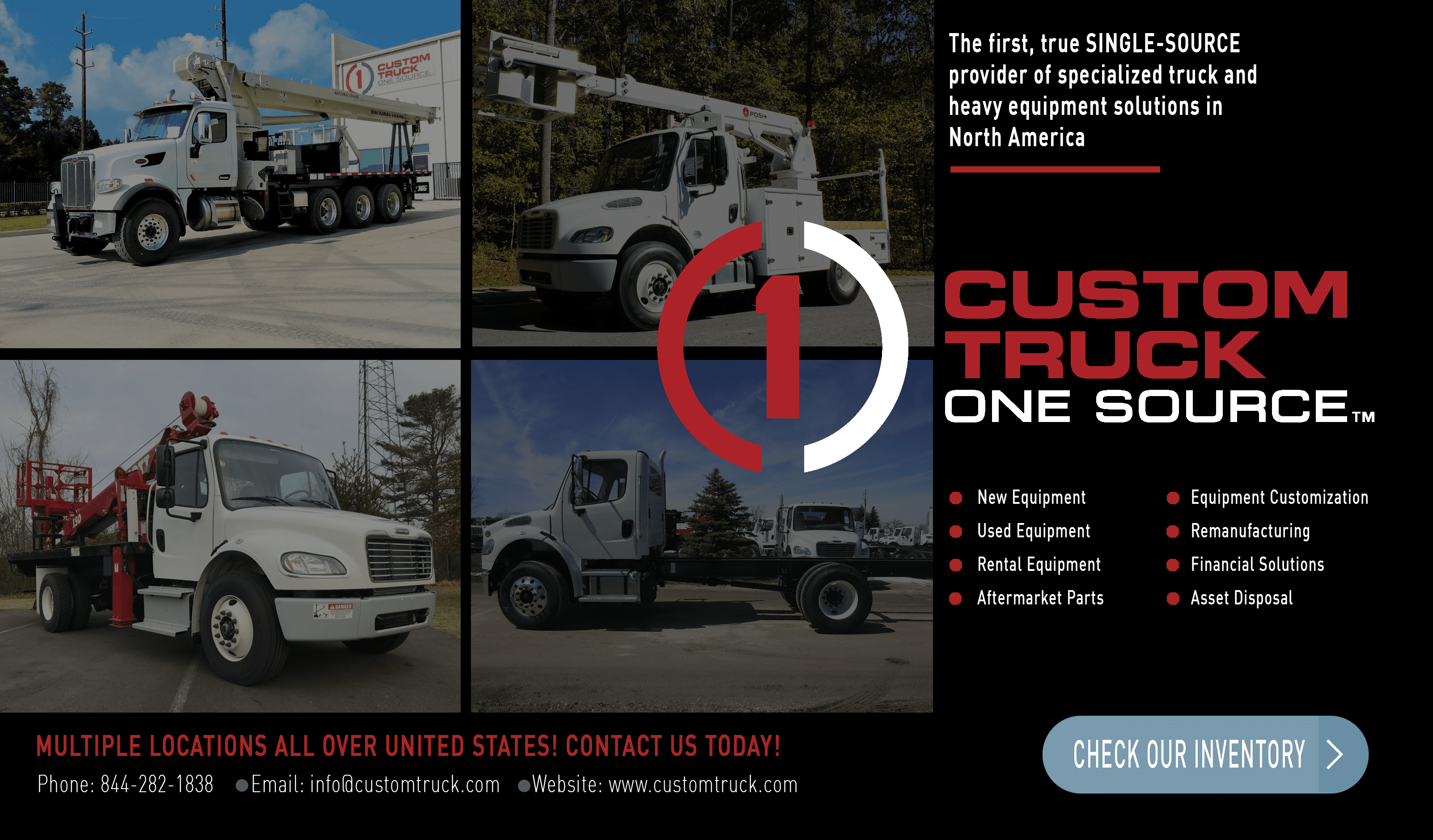

At Custom Truck One Source, the nation’s one-stop shop for propane transportation trucks, we try to raise awareness about proper handling and storage of propane during winter, and we’re simplifying OSHA (Occupational Safety And Health Administration) and CGA (Compressed Gas Association) regulations here in 18 easy-to-understand tips that will help you be responsible and safe when you’re around this flammable, hydrocarbon gas fuel:

TRANSPORTING PROPANE

Propane Transportation Equipment

Propane is a gas at standard temperature and pressure, but for transportation purposes, it is compressed to a liquid.

On a commercial scale, these types of equipment transport and distribute propane:

Road Tanker: Used for direct deliveries to high volume consumers, like petrol stations and large industrial users.

Ship: Large tankers called Gas Carriers or VLGCs (Very Large Gas Carriers).

Intermodal ISO Tank Container: LPG storage vessels mounted within an ISO standardized framework.

Rail: Tanker rail cars used to move large quantities of LPG in bulk.

Pipeline Transport: LPG pipelines running between gas fields and storage terminals.

Bobtail Tanker: For local bulk deliveries to end-users.

Reticulated Gas System: Central storage tanks supplying propane to a community via pipes, with each household equipped with a meter, which is similar to natural gas meters.

Cylinder Truck Delivery: Supplying gas bottles on an exchange basis via trucks to low-volume users.

Transportation Logistics and Safety

Commercial transportation logistics are naturally handled by trained and certified personnel, but what about transportation safety when people are personally bringing propane into their homes?

Propane cylinders are built to withstand a lot of external pressure during the transportation process, but accidents still happen, which is why certain precautions have to be taken when moving a cylinder around.

- Propane cylinders should always be in an upright position and strapped down during transportation. It should not roll around or bang against other objects.

- The valves must be closed, even if you think the cylinder is empty.

- Make sure there is sufficient ventilation during the transportation process, and don’t leave them lying around in a closed vehicle.

- Try to keep cylinders cool, and do not smoke near them.

- While unloading propane, transportation trucks should not park on busy streets, and they must stay at least 5 feet away from storage containers with the shut-off valves easily accessible.

PROPER USE

Whether the cylinder is a small container for home use or large enough to need a forklift to move, the hazards are the same, which means proper care has to be taken when using propane.

- Be aware of manufacturer’s guidelines (via their manual) about using the gas when handling propane-powered equipment.

- Only trained, certified, and authorized personnel should replace liquefied petroleum gas (LPG).

- While connecting and disconnecting propane cylinders from their hoses, personnel must wear proper eye protection gear and gloves (neoprene) to avoid risk of a freezer burn.

- Never use metal tools to change a cylinder, or exert too much force when trying to pry the valve open. Trying to modify or fix valves, or disassemble the cylinder in any way is a bad idea as well.

- Never strike a match or light a flame to check for leaks. If you don’t have a leak detector, you can use soap. Make a solution of half part dish soap and half part water and apply on hose connections to see if bubbles form, indicating a leak.

- Never paint propane cylinders a dark color. The reason they are painted in a light, reflective color is to reduce heat absorption from the sun.

- Don’t take empty propane cylinders for granted. They’re still hazardous and you must handle them carefully.

PROPER STORAGE

- According to OSHA specifications, you shouldn’t store cylinders near exits, stairways, entryways or close to high-traffic and busy areas.

- Propane cylinders must not be in the vicinity of other flammable or combustible materials.

- Ideally, cylinders storage should be off the ground, in flat areas that don’t collect water.

- Never store propane cylinders in an area of excessive heat (120 degrees or higher) or near a heat source.

- Check dates on the cylinder collars periodically to make sure that they’re not past the requalification date and replace or exchange cylinders that are out of date. If you notice leaks or signs of rust, you should replace them even if they’re under their requalification date.

- Make sure that there are fire extinguishers within easy access of propane storage.

Need Fuel Transportation Equipment?

- Bobtails (3,000, 3,200 and 3,499 Tank Sizes)

- Refined Fuel Trucks

- Load King Voyager (P Service Body)

Call Custom Truck One Source at 844-282-1838 or get in touch with us by clicking HERE. We’re the nation’s first, true single-source provider of specialized trucks and heavy equipment solutions.

With sales, rentals, aftermarket parts and service, equipment customization, remanufacturing, financing solutions, and asset disposal, our team of experts, vast equipment breadth and integrated network of locations across North America offer superior service and unmatched efficiency for our customers.