Lineworkers rely on dielectric materials to protect them from electrically charged environments when working on the grid. While fiberglass tools provide the needed strength and rigidity to work on the lines, rubber gear is used for its range of motion.

OSHA requires linemen to wear rubber gloves on the job, and they come in several different brands and types that Custom Truck One Source offers.

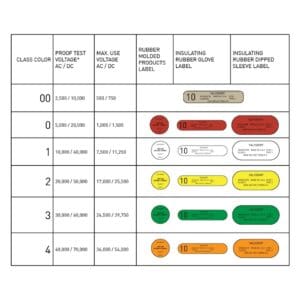

Beyond the sizes, brands and styles are levels of protection and insulation the gloves provide, they are determined by a system of six different classes with corresponding labeled colors. Classes range from “00,” which offers protection up to 500 AC (alternating current) volts, to Class 4, which protects up to 36kV AC.

All rubber gloves are to be tested every six months, or sometimes sooner, based on the customer’s safety policy. Testing is done at higher voltages than their ratings to ensure their dielectric properties haven’t deteriorated.

Custom Truck carries all the different classes. Class 3 is Custom Truck’s best seller for utility work. Colored with a green label, these gloves are made to work with conditions up to 26.5kV for alternating currents (AC. Class 4, with an orange label, is the highest level of protection, insulating against 36kV AC. These high-voltage gloves, and the others, must be compliant with ASTM standard D120. Gloves can come in different colors but always look at the colors of their tags to determine their voltage limits.

Custom Truck also offers a changeout program that lets customers regularly refresh their rubber glove inventory. Rubber gloves aren’t the only kind of hand protection regularly worn by linemen that Custom Truck has available.

Glove Protectors

Leather protectors are used over rubber and come in the same sizes as the different classes. Commonly made of cow or goatskin, these glove covers provide a layer of protection to the rubber material, which can be compromised by tears, cuts, gouges, and other damages on the job.

Never worn by themselves when working on lines, the protectors are shorter than the rubber gloves, leaving room for required safety clearance. The cuffs on protectors of the three lowest-voltage rubber gloves, classes 0, 00, and 1, line up 1” above the rubber cuff. For Class 2, that increases to 2”; 3” for Class 3; the gap needed for higher classes corresponds to the same. Additionally, some glove protectors are arc rated and have different degrees of ANSI cut resistance.

Glove Liners and More

Underneath the rubber gloves, linemen wear hand liners. Different materials are used for different purposes. Wool liners are used for warmth, while cotton liners are used in the summer to prevent perspiration. These undergarments are also used for improved comfort, to prevent chafing and extra protection.

Additionally, on their hands and gloves, linemen sometimes use glove dust, which is made of talc, to prevent moisture and stickiness.

For storage and transportation, there are several glove-specific bags that will keep gear from getting damaged.

Check out Custom Truck’s extensive selection of rubber gloves and other hand protection gear and accessories in our online store or call us at 800.842.0043.