It’s hurricane and tropical storm season. If you live in Florida or up and down the `Tornado Alley’ (Texas, Kansas, Oklahoma, Nebraska, Missouri, Iowa, Minnesota, Wisconsin, Indiana etc.), you already know what that means: possible roof damage.

How Storms Cause Roof Damage

Roofs are going to be under threat during severe weather events that can occur any time – or multiple times! — between now and November 30. High winds will tear, lift and curl shingles, breaking their seal bonding. This can subsequently leave the roof deck and underlayment exposed to the mercy of the elements. Hail will cause dents or dimples on the roof. It will shift the protective granules that were in place to protect against rain damage. Additionally, there will be water damage, causing mold that can threaten a whole building’s structure.

The job of re-roofing not one or two but dozens of homes and commercial buildings after such natural disaster events is a massive task.

This is where `roofing conveyors’ come in.

Roofing Conveyors

Using manual methods like platforms and pulleys to haul shingles, tools, bricks, fabric and other material to the rooftop is a thing of the past.

Roofing conveyors speed up the whole loading process making repairing damage quick, easy and safe. And bringing down heavy and unwieldy salvage is just as safe and efficient as placing new material.

Load King, the leading manufacturer and supplier of trailers and heavy equipment, has developed the Premier Roofing Conveyor in partnership with Richmond Conveyors and leading chassis manufacturers to deliver a state-of-the-art conveyor solution to the roofing industry.

The units range from 31 ft to 43 ft and come with a number of new features to complete a wider variety of applications.

Features and Benefits

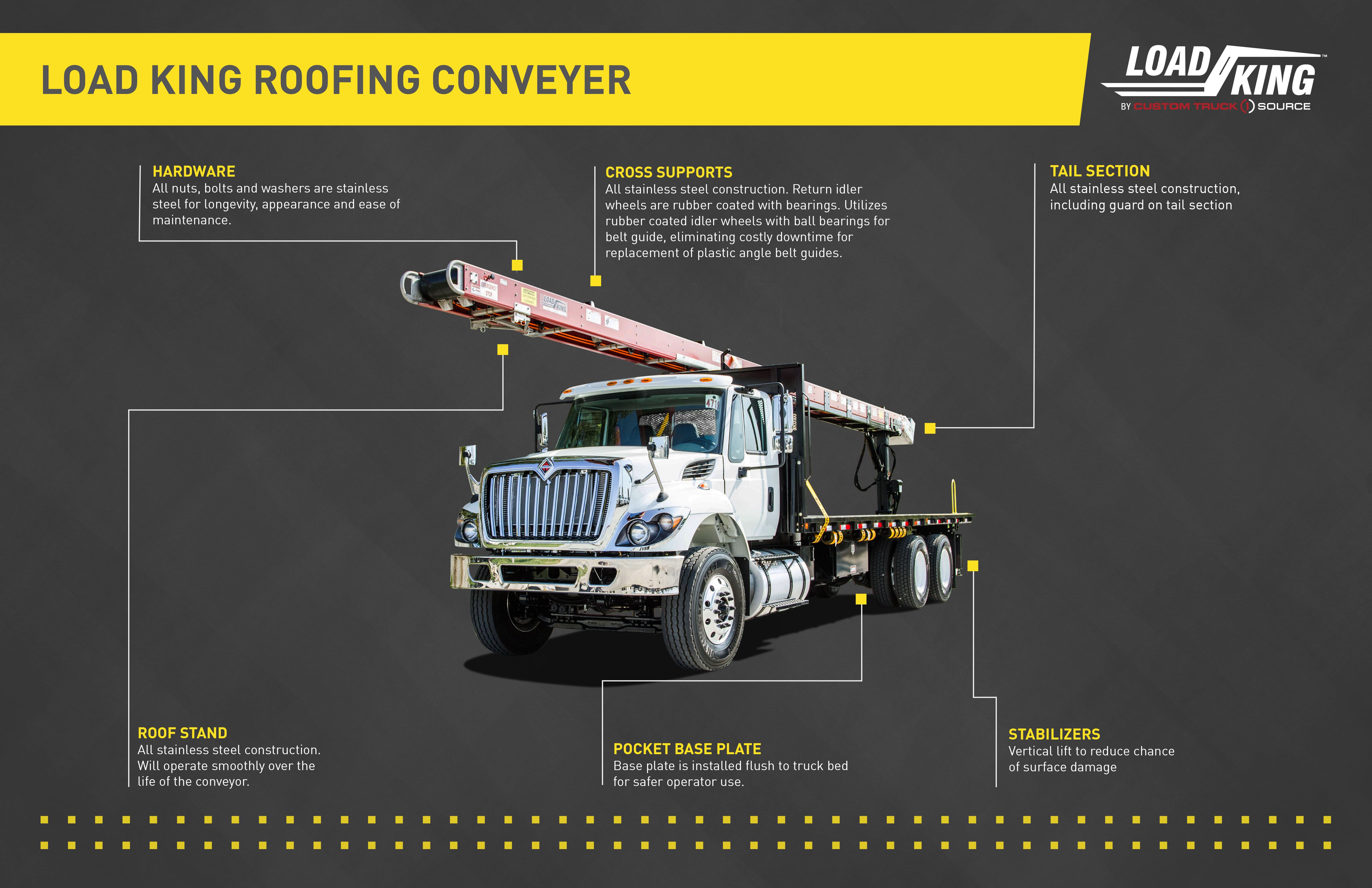

- Stabilizers: Vertical lift to reduce chance of surface damage.

- Head Section: Stainless steel support plates & hinge cover remain free of rust. Sprockets are removable.

- Head Section Pulley: All aluminum constructed drum style pulley with ¼” belt lagging.

- Tail Section: All stainless steel constructed guard will not rust. Steel V-groove guided drum style belt pulley.

- Head And Tail Pulleys: Heavy duty 4-bolt pillow block style bearing holder and bearing with grease zerk.

- Cross Supports: Hydraulic hose routing through the frame structure are captive in a holder.

- Paddles: Stainless steel paddle with rubber facing for better grip and less slippage.

- Roof Stand: All stainless steel construction. Will operate smoothly over the life of the conveyor.

- Hardware: All nuts, bolts and washers are stainless steel for longevity, appearance and ease of maintenance.

- Valve Controls: Valves are located higher up on the post for comfortable conveyor operation.

- Pocket Base Plate: Base plate is installed flush to truck bed for safer operator use.

- Rotation Mechanical Components: Post is integrated directly into the frame of the truck bed, utilizing a fixed drive motor, grease points and less hose movement. Rotation components and drive motor are accessible via a removable plate for easy access.

“Load King’s Premier Roofing Conveyor accelerates any roofing project with fast and efficient material handling,” says Dave Taff, Vice President of Building Materials at Custom Truck One Source. “And right now, we are keeping units on standby for companies who want to be prepared for the upcoming storm season roof damage with the most critical pieces of equipment at hand.”

Get Your Conveyor From Custom Truck One Source

Let us help you weather-proof your roofing business with a smart solution that will keep you on top of the job – no matter how hard the storms hit!

Check out the Load King Premier Roofing Conveyor by clicking HERE.

To request a quote, click HERE. Or call us at 855-787-7819 for more information.