The need to dig narrow and deep holes came about during the 1940s with the build-out of the American electrical grid.

You can see the need for these specialized trucks. They are true multitaskers. Read on to learn about the many benefits and features of digger derricks in this article.

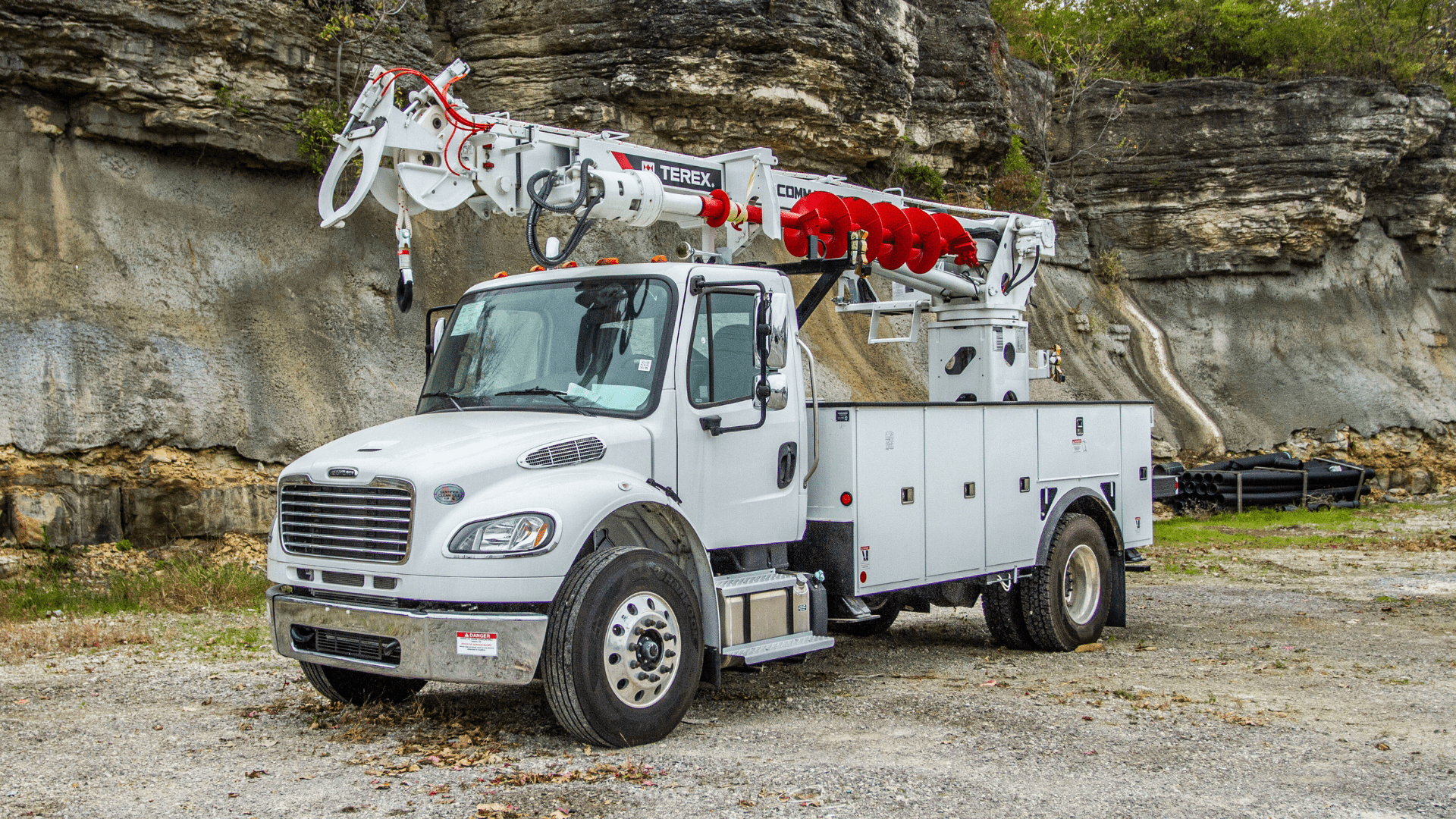

Anatomy of Digger Derricks

They use a hydraulic winch to lift objects from the ground much like a small crane does. The amount of lift a digger can handle is called sheave height, also known as working height.

These hydraulic trucks use a boom with an attached auger. Atop the boom sits a bucket for a worker.

Outriggers lower the center of gravity of the boom so that it doesn’t fall over. This becomes especially important on unlevel ground, and in windy conditions.

Digger Derricks Benefits

These trucks are mainstays of the oil and gas, construction, and telecom industries. They perform several different, but related tasks:

Utility Pole Installs

They dig deep, narrow holes for telephone and utility poles. Common digger derricks dig up to 10 feet deep and 18 inches in diameter.

These trucks can be fitted with various sized augers depending on how deep and wide a hole each project requires.

Boom Work

The auger works from a hydraulic boom that also lifts workers to telephone or electrical wires for installations and repairs.

The boom is also perfect for lifting workers to trim tree branches away from electrical and telephone wires.

Hoisting

Once the hole has been dug, these trucks can lift and move heavy utility poles and other materials. Workers use the digger derrick to position the pole for proper installation into the hole that has been prepared for it.

Other Uses

Digger derricks often get used in digging out tree stumps. A digger derrick also makes a great choice for digging shallow wells. These derricks can take workers underground and aid in fixing potholes in roads.

Different Types of Digger Derricks

Digger derricks differ mainly in the capacity that they can handle. But, they also differ in the kind of ground they can handle.

Distribution

These have sheave heights up to 50 ft. Distribution-sized derricks are very common in the electrical line and telecom industry.

Transmission

These derricks are larger than distribution models. They have sheave heights of up to 60 feet.

Pressure Diggers

Choose these when digging through tough ground and rock. These use a wider auger of up to 6 feet in diameter. They dig deeper, up to 60 feet in some cases.

These heavy-duty diggers get used for foundations and other projects requiring wider and deeper holes.

Backyard Diggers

Built for job sites in tight spaces, these will have less sheave height than other models, typically between 40 and 48 feet.

Track Diggers

Choose these when working in swampy areas or otherwise difficult terrain. If the work area is a place you cannot reach with tires, you need a tracked digger.

One of the Most Useful Industrial Machines

Digger derricks enjoy unmatched versatility. Instead of needing three or four different machines, you can do it all with one.

When it comes time for you to buy a digger derrick, contact Custom Truck, the largest single source of commercial trucks and equipment.