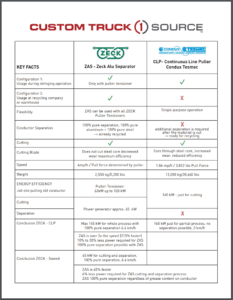

Zeck Aluminum Separator (ZAS) – The ZAS “Harvester”

The Zeck Aluminum Separator (ZAS) is a small machine that works behind a puller (Zeck or Condux) used to separate the aluminum from the steel cable core. The Zas “Harvester” chops up the separated aluminum into prime size pieces and also uses a winder with split reel to wind up the steel core for disposal. This offers the power company a quick and easy way to get prime aluminum price for their scrap conductor wire with minimal time and labor invested.

The ZAS is positioned between the puller-tensioner and a reel winder/drum stand during the stringing operation or between two reel winders/drum stands at the scrap shop or the builder’s yard. The conductor passes through the ZAS, the aluminum layers are scraped off and cut into aluminum pieces of 1 – 2.75 inches and are disposed to the side via a conveyor belt into big bags or containers. The undamaged steel core is then reeled onto the reel winder/drum stand. This way, the separation of pure materials can be done during the stringing operation! The max. rope speed is 3 mph.