The recommendations and guidelines presented in this comprehensive storm season guide are based on industry best practices and Custom Truck One Source’s extensive experience serving utility, telecommunications, infrastructure, and emergency response sectors. While these recommendations are designed to enhance safety and operational readiness during severe weather events, they should be used in conjunction with—not as a substitute for—all applicable federal, state, and local laws, regulations, and emergency protocols. Each organization must ensure compliance with relevant business continuity requirements, occupational safety standards, and emergency response mandates specific to their jurisdiction and industry.

Custom Truck One Source encourages all readers to consult with legal counsel and regulatory authorities to ensure full compliance with applicable laws during emergency situations. The safety of personnel and the public must always remain the top priority in any emergency response effort.

Regional Mutual Assistance Groups: How Utilities Unite in Times of Crisis

The utility industry faces unprecedented challenges as climate change intensifies storm patterns and extreme weather events become more frequent and severe. When natural disasters strike, power outages can last for days or even weeks, leaving entire communities without electricity. However, utility companies have evolved their disaster response strategies significantly since 2020, transforming how they unite through Regional Mutual Assistance Groups (RMAGs) to restore power faster than ever before.

Recent storms like Hurricane Milton in October 2024 showcased the remarkable evolution of mutual aid coordination, with over 50,000 utility workers from across North America mobilizing within 72 hours to restore power to millions of Florida residents. This response demonstrated how far RMAG protocols have advanced since the early days of hurricane recovery.

Being a member of an RMAG means no utility company must battle crises alone. Back-up resources like skilled workers, trucks, equipment, data, and expertise are always available from other member companies through increasingly sophisticated coordination systems.

The power system is an interconnected network, and utilities working in unison during an emergency event can now restore service more efficiently than ever before, thanks to digital coordination platforms and real-time data sharing.

Today’s mutual assistance programs have become highly standardized and digitally coordinated, a dramatic evolution from the ad-hoc responses of previous decades.

The mutual response efforts during recent storms including Hurricane Ian (2022), Winter Storm Uri (2021), and Hurricane Milton (2024) prove that modern RMAG coordination has reached new levels of efficiency. Utilities now deploy crews and support teams using AI-powered logistics platforms, sending precisely the right resources to exactly where they’re needed most.

Enhanced Benefits of Modern RMAG Partnerships

Today’s RMAG partnerships offer even more advantages than traditional mutual aid:

- Cost Effectiveness: Utility companies can optimize their permanent staffing while accessing surge capacity during emergencies through sophisticated resource-sharing algorithms that predict needs before storms make landfall.

- Advanced Knowledge Sharing: Modern RMAGs utilize cloud-based platforms for real-time information sharing, including weather data integration, damage assessment photos, and crew deployment tracking. This elevates response coordination to unprecedented levels of precision.

- Technology Integration: RMAGs now coordinate drone deployments for damage assessment, share satellite imagery for strategic planning, and use mobile apps for real-time crew communication across multiple utility companies.

- Cross-Border Cooperation: Recent storms have seen enhanced cooperation between U.S. and Canadian utilities, with streamlined border crossing procedures and shared equipment standards enabling faster international mutual aid response.

How Modern RMAG Agreements Work: The Three-Phase Evolution

Pre-Event: Predictive Coordination

Today’s natural disaster prediction capabilities far exceed those available just five years ago. Advanced weather modeling from the National Weather Service, enhanced satellite imagery, and AI-powered pattern recognition provide utilities with longer lead times and more accurate impact predictions.

Power companies now use machine learning algorithms to analyze historical storm data and predict equipment needs before storms arrive. Digital RMAG platforms automatically suggest resource allocations based on predicted storm paths, population density, and infrastructure vulnerability assessments.

These groups now deploy pre-positioned equipment to strategic locations and use mobile command centers that can be rapidly relocated as storm conditions change.

During the Event: Real-Time Digital Coordination

When disasters strike, modern RMAGs operate through integrated command centers that provide real-time visibility into restoration progress across multiple states. Priority restoration follows enhanced protocols that consider not just customer count, but also community resilience factors including medical facilities, emergency services, and critical infrastructure.

Drone technology enables rapid damage assessment without putting crews at risk, while mobile apps allow field teams to instantly report conditions and receive updated assignments. AI-powered resource allocation ensures crews are deployed to locations where they can restore power to the maximum number of customers most efficiently.

Social media monitoring and customer outage reporting apps provide utilities with unprecedented visibility into community needs during restoration efforts.

After the Event: Advanced Analytics and Continuous Improvement

Post-storm analysis now incorporates big data analytics to identify patterns and improvement opportunities. Utilities use performance metrics and customer feedback to refine their mutual aid protocols continuously.

Machine learning algorithms analyze response data to identify optimal crew deployment strategies, equipment positioning, and communication protocols for future events. This data-driven approach enables each storm response to be more effective than the last.

Looking Forward: The Future of Mutual Aid

The utility industry continues to innovate its mutual aid approaches:

- Blockchain Technology: Some RMAGs are piloting blockchain systems for transparent resource sharing and automated billing between utilities

- Autonomous Vehicles: Testing of autonomous utility vehicles for equipment transportation during dangerous conditions

- Advanced Materials: New power line and equipment designs that better withstand extreme weather, reducing mutual aid needs

- Community Resilience Integration: Coordination with local emergency management agencies and community organizations for more comprehensive disaster response

Our Role in Supporting Modern Mutual Aid

We at Custom Truck One Source are proud to support this evolved mutual aid network with our comprehensive fleet of utility and telecom equipment. Our digital inventory management system provides real-time equipment availability to RMAG coordinators, ensuring the right trucks and specialized equipment are positioned exactly where they’re needed.

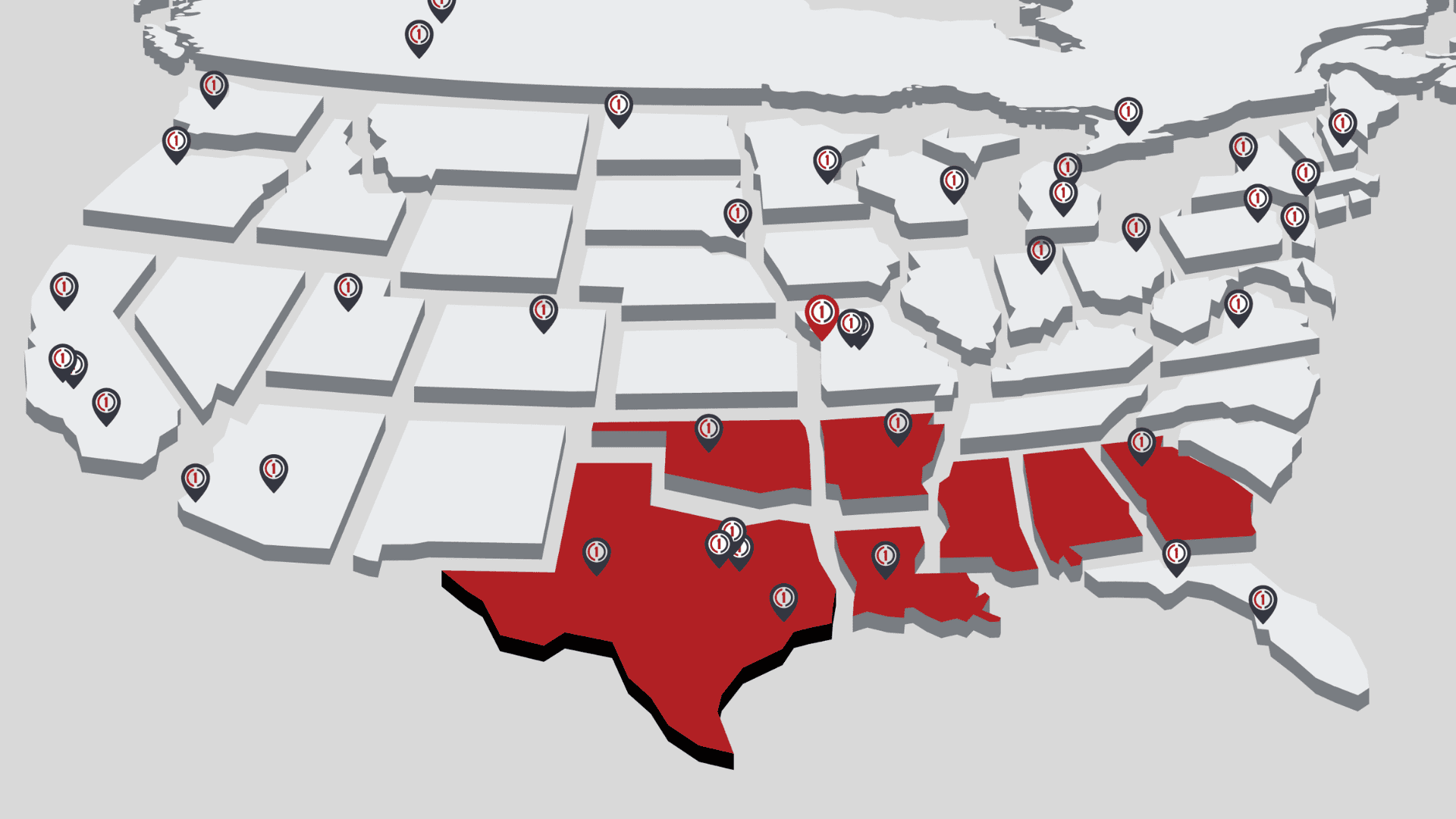

Our network spans throughout North America, with strategically located equipment depots that support rapid deployment during emergency events. We’ve integrated our systems with major RMAG coordination platforms, enabling automatic equipment requests and streamlined logistics during disaster response.

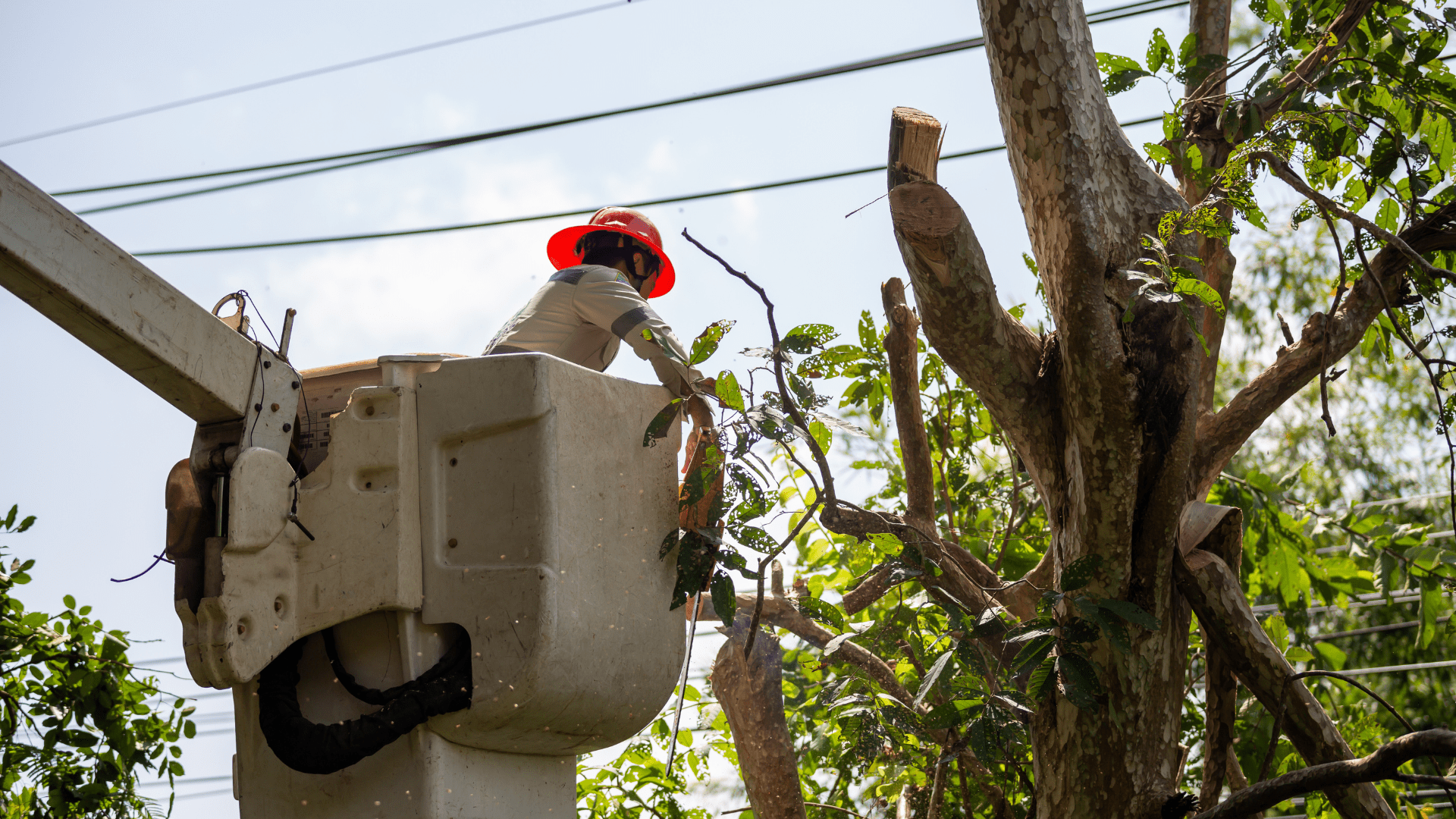

Whether utilities need bucket trucks, digger derricks, cable pullers, or specialized storm response equipment, our modern fleet management technology ensures rapid deployment to support mutual aid operations wherever they’re needed most.

For more information about our emergency response equipment and RMAG support services, contact Custom Truck One Source today.

Getting the Job Done: Restoring Power and Utilities After Tornadoes

Every year, seasonal storms and tornadoes cause devastating destruction across the United States. Recent tornado outbreaks, including the December 2024 events across multiple states and the ongoing threat of severe weather in 2025, demonstrate the critical importance of rapid power restoration. While first responders attend to immediate safety needs, restoring power and utilities after tornadoes remains the specialized work of utility companies equipped with advanced technology and coordination systems.

Modern tornado recovery now involves sophisticated damage assessment technologies including drone surveillance, satellite imagery analysis, and AI-powered resource allocation that can restore power to affected areas 40-60% faster than traditional methods used just five years ago.

It is vital that utility companies restore power quickly after a tornado strikes. Loss of electricity affects water treatment facilities, hospital operations, and essential communication systems that communities depend on for recovery coordination.

Understanding the comprehensive approach utility companies now take to restore power after disasters reveals how technology and planning have revolutionized disaster response. Keep reading to discover how modern tornado recovery works.

Advanced Pre-Disaster Planning

The foundation of effective tornado response begins with sophisticated predictive planning that goes far beyond traditional storm tracking. Modern utility companies use machine learning algorithms to analyze weather patterns, historical tornado data, and infrastructure vulnerabilities to create dynamic response plans.

AI-Powered Risk Assessment: Utilities now employ artificial intelligence to identify the most vulnerable sections of their grid based on equipment age, terrain, and historical storm damage. This allows for proactive equipment positioning and crew deployment before storms develop.

Digital Twin Technology: Many utilities have created digital replicas of their entire electrical grid, allowing them to simulate tornado impacts and test restoration strategies virtually before implementing them in real-world scenarios.

When it comes to pre-disaster planning, utility companies start by identifying priority restoration areas using sophisticated criteria:

- Life Safety Infrastructure: Hospitals, emergency services, water treatment facilities, and communication centers

- Community Resilience Hubs: Schools, community centers, and facilities that serve as emergency shelters

- Economic Impact Minimization: Major employers and critical business infrastructure

- Social Vulnerability Factors: Areas with elderly populations, medical equipment users, and limited transportation options

Technology-Enhanced Implementation

As soon as tornado development is detected through enhanced Doppler radar and satellite systems, utility companies activate their comprehensive response protocols. Advanced weather modeling now provides 6–12-hour advance notice for crew positioning and equipment staging.

Drone Deployment: Unmanned aerial vehicles are now pre-positioned to conduct immediate post-tornado damage assessment, providing real-time imagery and data to restoration teams without exposing workers to dangerous conditions.

Mobile Command Centers: Self-contained command vehicles equipped with satellite communication, weather monitoring equipment, and digital coordination systems can be rapidly deployed to tornado-affected areas to coordinate multi-utility response efforts.

Companies use predictive analytics to determine optimal staging locations and estimate resource requirements based on tornado intensity, path width, and affected infrastructure density.

Enhanced Mutual-Aid Coordination

The mutual-aid approach has evolved significantly since 2021, incorporating digital platforms that enable real-time resource sharing and coordination across utility companies.

Digital Resource Matching: Advanced algorithms now match available crews and equipment with specific restoration needs, considering factors like crew specializations, equipment compatibility, and geographic proximity.

Integrated Communication Systems: Utilities participating in mutual aid now use unified communication platforms that enable seamless coordination between different companies’ crews, eliminating the communication barriers that previously slowed restoration efforts.

Under modern mutual assistance programs, utility companies can mobilize resources with unprecedented speed and precision. Recent tornado responses have seen crews from over 20 states coordinating through centralized digital platforms to restore power to affected communities.

Advanced Steps to Power Restoration

Modern tornado recovery follows an enhanced five-step process that incorporates new technologies and methodologies:

Step 1: Automated Damage Assessment

Before crews enter potentially dangerous areas, utilities now deploy drones equipped with high-resolution cameras and thermal imaging to assess transmission tower and power line damage. AI-powered image analysis can identify specific types of damage and estimate repair requirements within hours of tornado passage.

Traditional transmission tower inspection that once took days can now be completed in hours, enabling faster restoration planning and crew deployment.

Step 2: Smart Grid Integration

Modern distribution substations incorporate smart grid technology that provides real-time status updates and can often be restored remotely once transmission issues are resolved. Advanced sensors and automated switching systems can isolate damaged sections while maintaining power to unaffected areas.

Predictive Maintenance Integration: Smart sensors can identify equipment that was stressed but not destroyed by tornadoes, enabling utilities to replace components before they fail and cause secondary outages.

Step 3: Dynamic Supply Line Management

Main distribution supply lines now incorporate smart switching technology that can automatically reroute power around damaged sections. GPS-enabled fleet management systems direct repair crews to specific problems with optimized routing.

Real-Time Load Balancing: As sections of the grid come back online, automated systems balance electrical loads to prevent equipment overload and ensure stable power restoration.

Step 4: Precision Tap Line Restoration

Repair of tap lines that serve individual neighborhoods now benefits from mobile apps that allow crews to report completion status instantly, enabling real-time coordination and preventing duplicate work assignments.

Customer Communication Integration: Automated systems now send restoration updates directly to customers’ mobile devices, reducing call center load and keeping communities informed about restoration progress.

Step 5: Smart Service Connection Restoration

Modern utilities use customer mobile apps and smart meter technology to identify individual service line issues quickly. Customers can report outages with precise location data, and smart meters can automatically indicate when individual services are restored.

Proactive Safety Verification: Before reconnecting individual services, utilities now use thermal imaging and electrical testing equipment to ensure customer electrical systems weren’t damaged by the tornado, preventing potential safety hazards.

Advanced Post-Disaster Analytics

Post-tornado analysis now incorporates comprehensive data analytics that examine not just physical damage patterns, but also response effectiveness, customer communication success, and crew safety metrics.

Machine Learning Optimization: Utilities analyze response data using machine learning algorithms to identify optimal crew deployment patterns, equipment positioning strategies, and communication protocols for future tornado events.

Community Resilience Assessment: Post-storm analysis now includes evaluation of how quickly communities recovered economic and social functions, informing future restoration priority decisions.

Climate Adaptation Planning: Utilities use tornado response data to inform long-term infrastructure hardening decisions and climate resilience planning.

Equipment Innovation for Tornado Response

Modern tornado response requires specialized equipment that didn’t exist during previous decades:

- All-Terrain Emergency Vehicles: Specialized trucks designed to navigate debris-filled areas with enhanced ground clearance and protective features.

- Portable Power Systems: Rapid-deployment generators and battery systems that can provide temporary power to critical facilities while permanent repairs are completed.

- Advanced Communication Trailers: Mobile command centers with satellite uplinks, drone charging stations, and coordination equipment.

- Storm-Hardened Equipment: New generation utility trucks with enhanced protection against extreme weather conditions.

The Future of Tornado Response

Utility companies are continuously advancing their tornado response capabilities:

- Autonomous Damage Assessment: Testing of autonomous vehicles for initial damage assessment in dangerous areas.

- Advanced Materials: Development of tornado-resistant power lines and equipment designs.

- Community Integration: Enhanced coordination with local emergency management and community organizations.

- Rapid Deployment Technology: Prefabricated power system components that can be quickly installed to restore service.

Supporting Modern Tornado Response

When tornado disasters strike, utility companies need equipment that matches the sophistication of their response plans. Custom Truck One Source provides specialized utility vehicles and equipment that enable rapid, effective tornado recovery.

Our modern fleet includes tornado response-specific equipment with enhanced safety features, GPS tracking for optimal deployment, and rapid-setup capabilities that reduce restoration time. We maintain strategic inventory positions across tornado-prone regions to ensure equipment availability when communities need it most.

Our digital fleet management system integrates with utility company dispatch systems, enabling automatic equipment requests and real-time tracking during emergency response operations.

Whether you need bucket trucks for line repair, specialized vehicles for debris-filled areas, or mobile command centers for coordination, Custom Truck One Source has the equipment and expertise to support your tornado response efforts.

Contact us today to learn more about our comprehensive tornado response equipment solutions, or explore our full range of utility equipment on our website.

Storm Season Preparation 2025: The Essential Guide for Modern Utilities

The 2025 Atlantic hurricane season, which officially began June 1st, is forecasted to be another highly active season with above-normal tropical storm and hurricane activity. With climate change intensifying storm patterns and recent storms like Hurricane Milton demonstrating the devastating potential of rapid intensification, preparation has never been more critical for utility companies and their communities.

Early seasonal forecasts predict 17-25 named storms for 2025, with 8-13 potentially becoming hurricanes. This level of activity requires unprecedented preparation and coordination among utility companies, emergency responders, and equipment providers.

The lessons learned from recent storm seasons have fundamentally changed how utility companies prepare for extreme weather events. Modern storm preparation now integrates advanced technology, predictive analytics, and enhanced mutual aid coordination to protect communities and restore power faster than ever before.

2025 Storm Season: What’s Different This Year

Several factors make 2025 storm preparation unique:

Advanced Forecasting Technology

- Enhanced Hurricane Track Prediction: New satellite technology and AI-powered models provide more accurate storm path predictions 5-7 days in advance

- Rapid Intensification Detection: Improved ability to predict when storms will rapidly strengthen, giving utilities more time to prepare

- Localized Impact Modeling: Computer models can now predict specific infrastructure impacts at the neighborhood level

Climate Change Adaptation

- Infrastructure Hardening Requirements: Many states now require utilities to demonstrate climate resilience in their storm preparation plans

- Extended Season Preparation: Warmer ocean temperatures mean storm season may effectively extend beyond traditional November 30th end date

- Unprecedented Storm Intensity: Utilities must now prepare for Category 6-level impacts even if the scale doesn’t officially exist

Essential Preparation Areas for 2025

- Advanced Equipment Readiness

Modern storm preparation requires sophisticated equipment inventory management.

Essential Fleet Components:

- Storm-Rated Bucket Trucks: Vehicles rated for high-wind operations with enhanced stabilization systems

- All-Terrain Restoration Vehicles: Specialized trucks capable of navigating flood-damaged and debris-filled areas

- Mobile Command Centers: Self-contained coordination vehicles with satellite communication and drone charging capabilities

- Autonomous Assessment Drones: Unmanned systems for initial damage assessment without risking crew safety

- Rapid Deployment Generators: Trailer-mounted power systems for critical facility backup during extended outages

Enhanced Equipment Features for 2025:

- GPS tracking and real-time inventory management

- Storm-hardened communication systems

- Enhanced safety features for extreme weather operations

- Rapid deployment and setup capabilities

- Digital Coordination Systems

2025 storm preparation emphasizes digital technology integration.

Essential Technology Platforms:

- Integrated Weather Monitoring: Real-time feeds from multiple weather services with AI-powered impact prediction

- Dynamic Resource Allocation: Software that automatically suggests optimal crew and equipment positioning

- Customer Communication Systems: Automated outage reporting and restoration updates via mobile apps

- Mutual Aid Coordination Platforms: Digital systems for requesting and coordinating resources across utility companies

- Enhanced Safety Protocols

Worker safety in extreme weather conditions requires evolved protocols.

Advanced Safety Measures:

- Pre-Storm Health Screening: Enhanced protocols to ensure crew fitness for extended emergency operations

- Real-Time Weather Monitoring: Individual crew-level weather alerts and safety notifications

- Wearable Safety Technology: Smart helmets and vests with environmental monitoring and emergency alert capabilities

- Mental Health Support: Recognition and support for the psychological stress of disaster response work

- Community Resilience Integration

Modern storm preparation extends beyond utility operations.

Community Coordination Elements:

- Emergency Shelter Power Planning: Pre-identified critical facilities requiring priority restoration

- Medical Equipment User Registry: Database of customers with life-supporting medical equipment

- Community Communication Networks: Multi-channel communication systems for emergency updates

- Social Vulnerability Mapping: Identification of neighborhoods requiring enhanced support during outages

Pre-Season Preparation Checklist for 2025

60 Days Before Season Peak (April-May)

Equipment and Infrastructure:

- Complete storm equipment inspections and certifications

- Update GPS tracking and fleet management systems

- Test backup communication systems and emergency protocols

- Calibrate drone systems and update damage assessment software

- Verify integration with mutual aid digital platforms

Personnel and Training:

- Complete storm response training for all crew members

- Update emergency contact databases and communication trees

- Train crews on new safety technology and protocols

- Coordinate with mutual aid partner utilities on resource sharing agreements

30 Days Before Peak Season (May-June)

Operational Readiness:

- Finalize staging area locations and equipment pre-positioning

- Test customer communication systems and mobile apps

- Conduct AI-powered storm response simulations

- Update community emergency shelter and critical facility databases

Supply Chain and Logistics:

- Verify parts inventory and supplier emergency protocols

- Confirm autonomous equipment and drone spare parts availability

- Test rapid equipment deployment procedures

- Coordinate with equipment rental partners for surge capacity

During Active Threats (Storm-Specific)

72 Hours Before Landfall:

- Activate storm command centers and communication protocols

- Begin equipment pre-positioning based on forecast models

- Deploy advanced weather monitoring equipment to predicted impact areas

- Notify mutual aid partners of potential resource needs

24 Hours Before Landfall:

- Complete final equipment positioning and crew assignments

- Launch pre-storm drone reconnaissance if safely possible

- Activate customer communication systems with pre-storm updates

- Finalize coordination with emergency management agencies

Technology Integration for 2025 Storm Season

This year’s storm preparation emphasizes technology integration.

Artificial Intelligence Applications

- Predictive Damage Modeling: AI systems that predict likely infrastructure damage based on storm characteristics

- Resource Optimization: Machine learning algorithms that optimize crew deployment and equipment allocation

- Customer Impact Analysis: Predictive systems that identify customers most likely to experience extended outages

Enhanced Communication Systems

- Multi-Modal Alert Systems: Integration of text, voice, social media, and app-based customer communications

- Real-Time Translation Services: Automated translation for diverse community communication needs

- Social Media Monitoring: AI-powered systems that monitor social media for real-time community needs assessment

Advanced Assessment Technology

- Satellite Imagery Integration: Real-time damage assessment using commercial satellite services

- Thermal Imaging Systems: Equipment that identifies electrical system damage not visible to standard cameras

- LiDAR Mapping: Precision mapping technology for assessing infrastructure damage and planning restoration routes

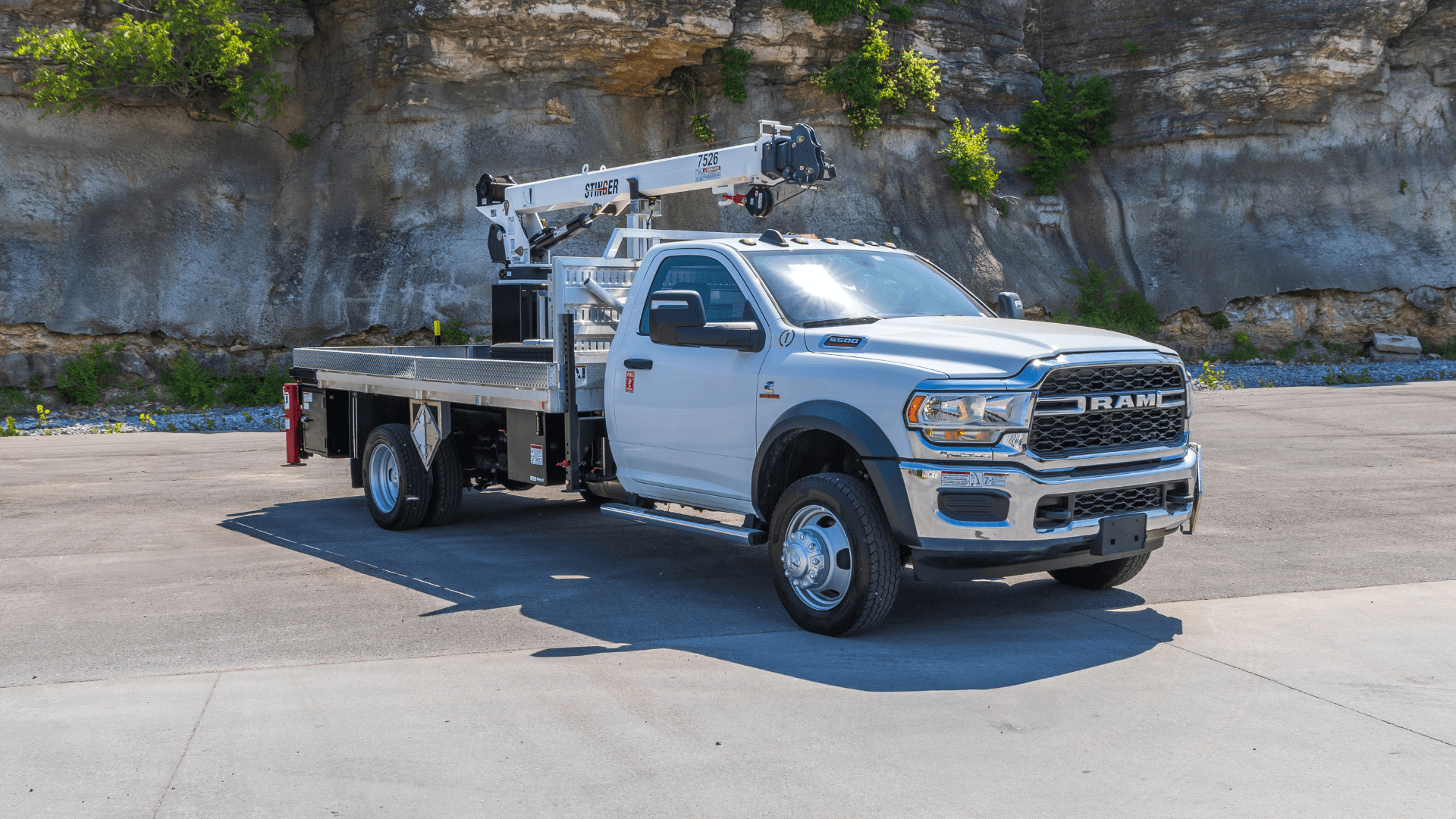

Supporting Your 2025 Storm Season Preparation

Custom Truck One Source stands ready to support your enhanced storm preparation needs with our comprehensive fleet of modern utility equipment. Our 2025 storm season offerings include the following.

Advanced Storm Response Equipment:

- Latest-generation bucket trucks with enhanced stability and safety systems

- Storm-hardened communication vehicles with satellite connectivity

- All-terrain vehicles designed for post-storm debris navigation

Enhanced Services:

- Digital fleet management with real-time equipment tracking

- Rapid deployment logistics with pre-positioned equipment

- Integration with mutual aid coordination platforms

- 24/7 emergency equipment dispatch and support

Strategic Positioning: Our equipment is strategically positioned across hurricane-prone regions to ensure availability when you need it most.

Preparing for an Unprecedented Season

The 2025 storm season represents a new era in weather challenges and response capabilities. With enhanced forecasting, advanced technology, and improved coordination systems, utility companies are better prepared than ever to protect their communities and restore power quickly after storms.

Success in 2025 will depend on embracing new technologies while maintaining the core values of safety, community service, and mutual support that have always defined the utility industry’s storm response.

Custom Truck One Source is your partner in navigating this challenging season. Contact us today to discuss your storm preparation equipment needs and ensure your team has the tools necessary for an effective 2025 storm season response.

How Advanced Roofing Conveyors Are Revolutionizing Post-Storm Recovery

The 2025 Atlantic hurricane season is forecast to be above-normal, with NOAA predicting 13 to 19 named storms (with a 60% chance of an above-normal season) compared to an average season of 14 storms. The forecast calls for up to 10 hurricanes, with 3-5 expected to reach Category 3 intensity or greater. From Florida’s Gulf Coast to the expanded reaches of “Tornado Alley” (spanning Texas through the upper Midwest), property owners are bracing for what could be another challenging storm season running through November 30.

The Evolving Nature of Storm Damage in 2025

Today’s severe weather events are becoming increasingly unpredictable and intense. High winds continue to tear, lift, and curl shingles, breaking their protective seal bonds and exposing roof decks to the elements. Hail creates damaging dents and shifts protective granules that guard against water infiltration. But beyond traditional damage patterns, we’re seeing new challenges emerge as climate patterns shift and building materials evolve.

Water damage remains a critical concern, with modern building practices requiring faster response times to prevent mold growth that can compromise entire structural systems. The insurance industry has also tightened its grip on roofing claims, making efficient, documented repairs more crucial than ever for contractors and property owners alike.

The task of re-roofing dozens of homes and commercial buildings after major weather events has grown into a sophisticated operation requiring advanced equipment and streamlined processes.

The Technology Revolution: Modern Roofing Conveyors

The days of hauling materials up ladders with pulleys and platforms are definitively over. Today’s roofing industry demands speed, safety, and efficiency that only advanced conveyor systems can provide.

This shift comes at a time when the industry is experiencing significant growth. The U.S. roofing market is estimated at $24.79 billion in 2025 and projected to grow at a compound annual growth rate of 6.17% through 2030. Metal roofing has become the second-most popular material for both residential and commercial roofs, with growth in commercial metal roofing systems expected to be significantly higher in 2025. Smart roofing systems with integrated sensors for real-time monitoring and energy-efficient materials are also reshaping the industry landscape.

Load King, the industry-leading manufacturer of specialized trailers and heavy equipment, has developed the Premier Roofing Conveyor in partnership with Richmond Conveyors and leading chassis manufacturers. This state-of-the-art system addresses the modern roofing industry’s need for versatility, durability, and efficiency. Load King’s conveyor now comes with the Load King Lightning PTO, an electric power take-off unit that enhances both environmental performance and workplace safety by reducing noise levels and emissions compared to traditional systems.

Premier Roofing Conveyor: Built for 2025’s Challenges

The Load King Premier Roofing Conveyor range spans from 31 to 43 feet and incorporates cutting-edge features designed for today’s diverse roofing applications.

Advanced Stability & Safety Features:

- Vertical-Lift Stabilizers: Engineered to minimize surface damage while maximizing stability

- Flush-Mounted Pocket Base Plate: Integrated seamlessly into truck beds for enhanced operator safety

- Elevated Valve Controls: Positioned for comfortable, ergonomic operation during extended use

Corrosion-Resistant Construction:

- Stainless Steel Components: Head section support plates, hinge covers, tail section guards, and all hardware resist rust and corrosion

- All-Aluminum Head Section Pulley: Drum-style design with ¼” belt lagging for superior durability

- Stainless Steel Roof Stand: Engineered for smooth operation throughout the conveyor’s lifespan

Enhanced Performance Features:

- Removable Sprockets: Simplified maintenance and replacement

- Heavy-Duty 4-Bolt Pillow Block Bearings: With grease zerks for long-term reliability

- Integrated Hydraulic Routing: Captive hose holders protect against damage

- Rubber-Faced Stainless Steel Paddles: Optimized grip reduces material slippage

Advanced Mechanical Integration:

- Direct-Frame Post Integration: Utilizing fixed drive motors with accessible grease points

- Removable Access Plates: Easy maintenance access to rotation components and drive motors

- Reduced Hose Movement: Minimizes wear and maintenance requirements

Prepare Your Business for an Active Storm Season

With industry analysts predicting continued growth in storm-related roofing work and the ongoing shift toward more durable, technology-integrated roofing solutions, having the right equipment on standby isn’t just smart business—it’s essential for staying competitive.

Custom Truck One Source maintains Premier Roofing Conveyor units ready for immediate deployment, ensuring contractors can respond quickly when storm damage strikes their service areas.

Get Equipped for 2025’s Opportunities

Don’t let equipment limitations slow your response to the growing demand for professional roofing services. Whether you’re handling traditional storm repairs or installing the advanced roofing systems that are increasingly popular in 2025, the Load King Premier Roofing Conveyor provides the efficiency and reliability your business needs.

Ready to upgrade your capabilities?

Stay ahead of the competition with equipment designed for today’s roofing challenges and tomorrow’s opportunities. Contact us today.