A customer inquired about using synthetic rope on our 80-160 Crossover Crane. Custom Truck One Source has experience with synthetic ropes on our insulated and utility aerial products, but we had not installed synthetic ropes on lifting cranes before. However, recognizing this would be a good option for other customers, we decided to explore it further.

An internet search (don’t we all start there now) turned up a few potential vendor partners. This particular customer decided that synthetic rope was the best option for their needs. However, You should research carefully if you plan to replace the wire rope on your crane with synthetic, and always follow the manufacturers’ requirements for breaking strength, size, etc. A Load King crane that is purchased with synthetic rope will have full warranty coverage. Approval is required to continue warranty coverage for a crane retrofitted with synthetic rope.

Synthetic rope is significant because it is lighter than wire rope, is more corrosion-resistant, and is easier to handle.

Our team at Custom Truck also liked the idea that hand injuries could be reduced by contacting broken wires. In addition, common wire rope issues like kinking and bird-nesting are eliminated. We found the rope did dive occasionally when reaving, but once reversed, we found no damage.

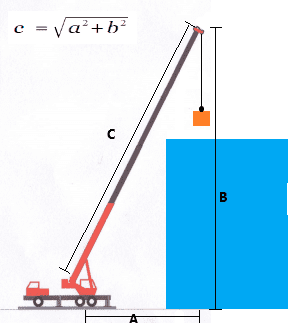

After some brief discussions with the vendors identified, we chose one to prototype a solution. The standard wire rope on our crane is 600 feet of 3/4” rotation resistant with a minimum breaking strength of 80,000 lbs. for a single line pull of 16,000 lbs. (with the required 5 to 1 safety factor). That led us to try a 7/8” rope with a solid core and a breaking strength of 84,000 lbs.

We wanted to try to keep our single line pull the same and we were concerned about the other rope’s ability to spool properly on the drum. While this rope was larger than our standard, we thought that there would be no problem with abrasion in our sheaves and guides. The rope also provides torque-neutral construction.

We ordered a couple of sets of the rope and tested one of our prototype machines (it’s good to be an OEM) to work with it. We set up a variety of configurations on the main boom with up to eight parts of the line. We also set up the bi-fold jib including offsets and did a variety of lifts. We had no issues with binding or abrasion in our tests. Even with a lighter rope, we used the same downhaul weights and blocks with no issues. An interesting benefit that we noticed was that since the rope didn’t need lubrication, the reaving changes were significantly cleaner.

Here are some things to consider.

The Winch drum attachment must be reviewed to make sure there are no sharp edges that can cut the rope. This holds true for the entire path of the rope. The synthetic rope is less forgiving with sharp edges. If you are retrofitting a crane, you may need to replace sheaves, guides, etc. that have the potential to damage the rope. Long-term exposure to UV, heat, and chemicals can have a negative effect on the synthetic rope. Be sure to follow the manufacturer’s recommendations for inspection, repair, and replacement.

Some care needs to be taken around the bend radius. We found that some of our tackle would violate the manufactures recommendations for minimum radius and bits and chocks were not all at the minimum ratio to rope diameter. Thoroughly inspect all tackle with the machine prior to considering the transition to synthetic rope.

Care is also required when reviewing the sheaves in the reaving system. V-groove sheaves were to be avoided according to this manufacturer, and they had minimum recommendations for sheave and groove diameter. In our case, the standard sheaves were able to be used.

When speaking with customers, we heard about issues with synthetic ropes being damaged by the Anti-Two-Block (ATB) weight vibrating while on the road. As a precaution, we added a storage bracket to the boom head for the ATB weight to make it easy to remove and store for transport.

The last hurdle for us was the minimum number of wraps on the drum. We have a standard third-wrap indicator on our crossovers; however, the manufacturer was recommending a minimum of ten wraps. We overcame the situation together with our winch and control system providers.

Following our testing and evaluation we decided to go with 3/4″ synthetic rope and reduce the line pull on the machine. The trade-off is a rope and reaving system that better complies with the winch and rope manufacturers’ recommendations and should provide customers with a satisfactory experience.

A new crane purchased with synthetic rope would come equipped with the LMI configured for the lower line pull. In the case of a retrofitted machine, a new set of reaving diagrams, hex files, and control system updates can be provided.

After this successful test, we feel confident in offering a synthetic rope option for any of our Load King Cranes.

Please contact your salesperson if you would like to know more.

Pictures attributed by Samson Rope.